By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

In the rapidly evolving manufacturing landscape, the demand for precision and efficiency is paramount. The steel sheet laser cutting machine has emerged as an essential tool for achieving these goals. According to a recent industry report by MarketsandMarkets, the laser cutting market is projected to reach $4.05 billion by 2026, highlighting a significant growth trajectory. This trend is driven by the increasing need for high-quality metal fabrication in sectors such as automotive, aerospace, and construction.

While many operators seek the most advanced technology, not all steel sheet laser cutting machines are created equal. Companies must carefully assess their needs, including material thickness and cutting speed. An analysis from Grand View Research suggests that the performance of laser cutting machines varies significantly, which can impact overall production efficiency. As businesses look to invest, it’s crucial to consider various options available on the market.

Despite the potential benefits, not every machine will meet long-term operational needs. Challenges such as maintenance complexities and initial costs can deter procurement. Evaluating these factors requires honesty and a willingness to reflect on past purchasing decisions. In 2026, finding the best steel sheet laser cutting machine will demand an informed and strategic approach. Understanding unique operational requirements is key to making the right choice.

Choosing the right steel sheet laser cutting machine requires careful consideration of various factors. One crucial aspect is the power of the laser. Higher power often leads to faster cutting speeds. However, too much power can burn or warp thinner materials. Balance is essential.

Speed and accuracy also matter. Some machines may cut quickly but lack precision. In contrast, others can provide intricate designs at a slower pace. It’s vital to assess your production needs. Explore your material thickness requirements. Ensure the machine can handle those variations.

Another factor to ponder is maintenance. Some machines require more frequent servicing than others. A reliable support system for repairs can save time and money. This is often overlooked during procurement. Additionally, consider the machine's software. Some systems have user-friendly interfaces, while others are complex. It’s best to test them before making a decision. Each consideration contributes to a better overall manufacturing process.

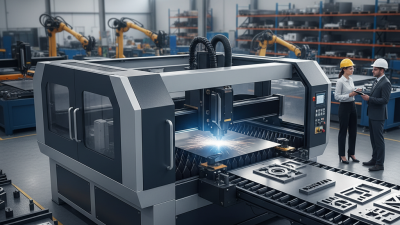

In 2026, the demand for steel sheet laser cutting machines continues to grow. With advancements in technology, manufacturers are focusing on precision and efficiency. Reports indicate that the global laser cutting machine market is expected to reach $5 billion by 2026, driven by industries such as automotive and aerospace. Steel sheet applications are increasing, as companies seek high-quality cuts with minimal material waste.

Among top brands, innovation is key. Many focus on integrating automation into laser cutting systems. This helps reduce labor costs and improve production speed. However, not all brands deliver the same quality. Some offer machines that are less reliable, leading to downtimes. A study from TechNavio suggests that 30% of companies experienced production delays due to machinery failures, raising concerns about equipment quality.

Investment in training is also crucial. Workers must understand how to operate these machines effectively. A report highlights that 25% of accidents in laser cutting operations result from inadequate training. Therefore, companies not only need to invest in machines but also in workforce development. Choosing the right machine involves weighing these factors carefully.

| Model | Power (W) | Max Cutting Thickness (mm) | Cutting Speed (m/min) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 1500 | 10 | 20 | 1200 | 30000 |

| Model B | 2000 | 12 | 25 | 1500 | 45000 |

| Model C | 3000 | 15 | 30 | 1800 | 60000 |

| Model D | 4000 | 20 | 35 | 2000 | 80000 |

| Model E | 6000 | 25 | 40 | 2500 | 100000 |

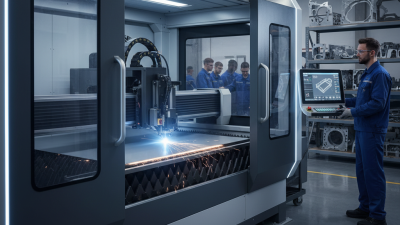

When choosing a laser cutting machine for steel sheets, certain features are crucial. Power levels significantly affect cutting speed and material thickness. Machines generally range from 500W to 6000W. A higher wattage allows for faster and cleaner cuts, especially in thicker materials. Most industry reports suggest that machines over 1000W are optimal for steel cutting projects.

Accuracy is another important factor. Laser cutting machines can achieve tolerances as tight as ±0.1mm. This precision is essential for industries that require intricate designs. Moreover, the beam quality influences the cut finish. A better beam quality often results in less post-processing, saving time and improving productivity.

Users often overlook compatibility with software and automation options. Integration with CAD programs can streamline operations. Additionally, some machines may only work well with specific materials. This limitation can impact the projects you undertake. The market shows that around 30% of users experience issues with material compatibility after purchase. Hence, understanding these specifics before making a decision is vital.

When exploring laser cutting technologies, it’s essential to understand their varying capabilities. Different laser types, such as fiber and CO2, offer unique advantages. Fiber lasers excel in cutting thin metals with precision, while CO2 lasers are often more versatile, handling non-metal materials efficiently. This differentiation can be critical for businesses aiming for efficiency and high-quality output.

Another consideration is cutting speed and thickness compatibility. Fiber lasers are known for their swiftness in cutting materials up to a certain thickness. However, beyond specific limits, their efficiency can diminish. In contrast, CO2 lasers can handle thicker materials, but may not match fiber lasers' speed on thinner sheets. It's vital to weigh these factors based on your operational needs and material types.

Additionally, the cost of ownership plays a significant role in the selection process. Initial investments for these machines can vary greatly. Maintenance costs, energy consumption, and operational efficiency should also be factored in. While some machines offer lower upfront costs, higher energy use can lead to inflated long-term expenses. Businesses must contemplate these trade-offs carefully to ensure they make a well-informed decision.

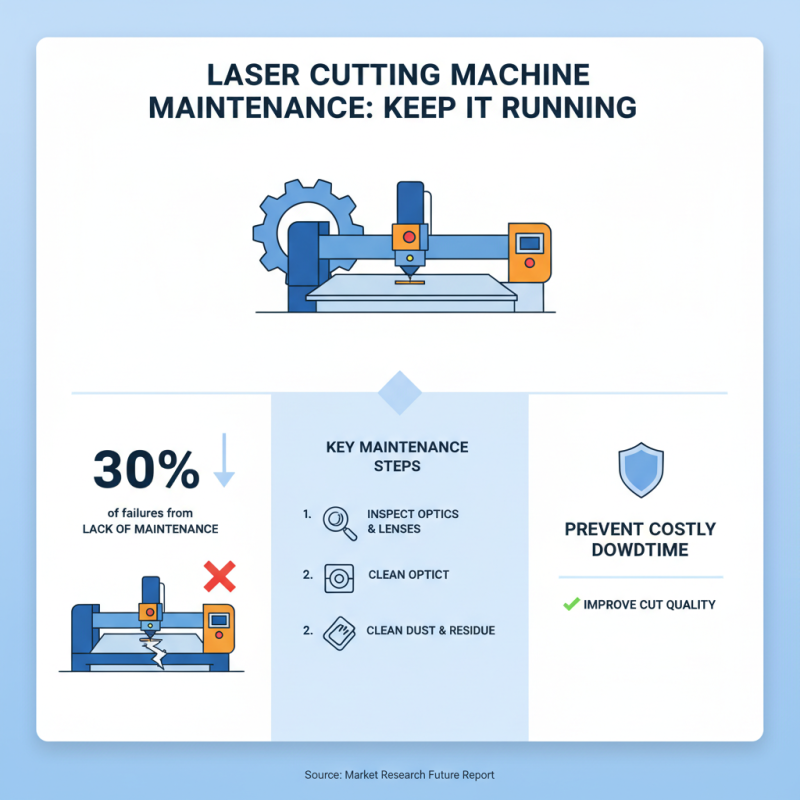

When operating a laser cutting machine, maintenance is crucial. Regular checks can prevent costly downtime. According to a report by Market Research Future, about 30% of laser cutting machine failures are due to lack of proper maintenance. Simple steps can help. Regularly inspect optics and lenses for cleanliness. Dust or residue can affect cutting quality significantly.

Safety should not be overlooked. Eye protection is essential to prevent damage from intense light. The Occupational Safety and Health Administration (OSHA) emphasizes the importance of using proper safety gear. Operators should wear gloves and aprons to protect against potential burns. Over half of reported accidents could have been avoided with correct safety measures in place.

Training is often inadequate. Many operators may not fully understand the machine's capabilities and limitations. Documented improvements in training can enhance safety by nearly 20%. Addressing these issues creates a safer work environment. Regular safety drills can help reinforce procedures and keep workers vigilant. Awareness and attention to detail are key in mitigating risks in laser cutting operations.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.