By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

In the world of modern manufacturing, the role of technology cannot be overstated. One machine leading this revolution is the laser sheet cutting machine. Experts affirm its significance. John Smith, a renowned industry professional, once stated, “Laser sheet cutting machines enhance precision and efficiency like never before.”

The advantages of laser cutting are numerous. It features high accuracy, reducing waste and cutting costs. Additionally, it allows intricate designs that traditional methods struggle to achieve. Yet, the operating costs and maintenance still raise concerns. Companies must weigh the benefits against potential drawbacks.

However, not all applications are perfect for this technology. Businesses need to evaluate their specific needs. The laser sheet cutting machine represents progress, yet careful consideration is essential for optimal use. It’s a powerful tool with great potential, but users must reflect on its practicalities and limitations.

Laser sheet cutting machines offer significant advantages for modern manufacturing. These machines provide precision that is hard to match. The ability to cut intricate designs with minimal waste improves material efficiency. This is especially important in industries where material costs are high. The laser technology also allows for faster production times. Efficiency in cutting can lead to quicker turnaround on projects.

Another key advantage is the flexibility in design. Manufacturers can execute complex shapes and patterns that may be impossible with traditional methods. This opens new doors for creativity. However, the initial investment in laser cutting technology can be a barrier for some businesses. They must consider their specific needs carefully before purchasing. The maintenance of the equipment also requires diligence. Regular checks and upkeep ensure optimal performance. Small errors can lead to larger issues down the line, impacting overall productivity.

| Advantage | Description | Impact on Manufacturing |

|---|---|---|

| Precision Cutting | Laser cutting provides high accuracy with minimal kerf width. | Reduces material waste and enhances product quality. |

| Versatility | Can cut a variety of materials including metals, plastics, and wood. | Improves manufacturing capabilities across multiple sectors. |

| Speed | Faster cutting speeds compared to traditional methods. | Enhances productivity and meets tight deadlines. |

| Automation | Easily integrated with automation systems for increased efficiency. | Streamlines the manufacturing process and reduces labor costs. |

| Reduced Heat Affected Zone (HAZ) | Minimizes thermal distortion and keeps materials cooler. | Preserves material integrity and reduces post-processing needs. |

Laser sheet cutting machines have revolutionized the manufacturing landscape, especially in terms of precision and accuracy. The technology behind these machines allows for incredibly fine cuts, which reduces material waste. This precision means that parts fit better together in assembly, leading to improved overall quality. For industries like aerospace and automotive, such accuracy is not just a benefit; it's a necessity.

However, achieving this level of precision requires trained operators. The machines can be intricate, and improper setup can lead to errors. Some users may struggle to fully understand the controls, resulting in less accurate cuts. Frequent training and updates on operational techniques are essential for maximizing effectiveness.

Moreover, while laser cutting provides clean edges and reduces the need for additional finishing processes, it may not be suitable for all materials. Certain metals can reflect the laser, causing unpredictable results. This limitation can be frustrating for manufacturers aiming for versatility in their production lines. Continuous experimentation and a willingness to adapt processes are vital for overcoming these challenges.

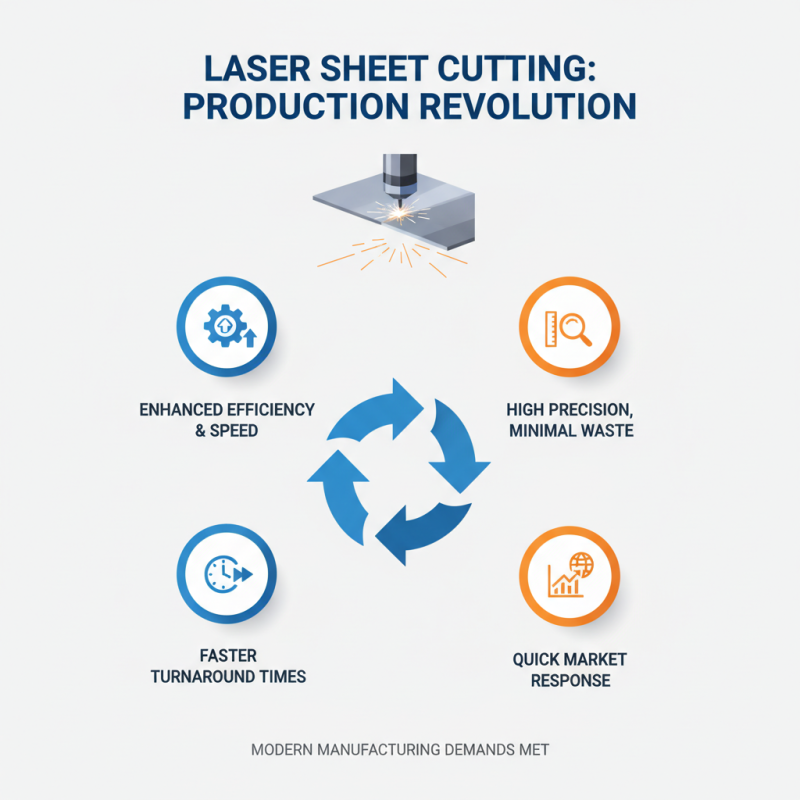

Laser sheet cutting machines are revolutionizing production lines. They offer enhanced efficiency and speed, which modern manufacturing demands. These machines cut materials with high precision. The result is minimal waste, a vital consideration for any operation. Faster turnaround times mean products reach the market sooner. This quick response to market changes is crucial in today’s fast-paced environment.

Operators must stay vigilant, as laser machines can present challenges. Training staff thoroughly is essential. Mistakes can lead to costly errors, especially with intricate designs. Regular maintenance is also necessary to ensure uninterrupted operation. Investing in these machines is not just about speed; it’s about combining quality and efficiency.

Interesting opportunities arise with increased automation. However, not every manufacturer may implement it seamlessly. Some may struggle, particularly smaller operations. They might find the transition daunting. Adapting to new technology requires time and patience. A balance between tradition and innovation must be struck for lasting success.

Laser sheet cutting machines offer exceptional versatility, making them a key asset in modern manufacturing. They can efficiently cut a variety of materials, including metals, plastics, and woods. This versatility allows manufacturers to adapt quickly to market demands. Whether it’s creating intricate designs in metal or precise shapes in acrylic, these machines handle diverse applications with ease.

The ability to work with different materials brings unique challenges. Each material requires specific settings and adjustments. For example, cutting aluminum may need a different power setting than cutting wood. Sometimes, this can lead to unexpected results. Manufacturers must regularly fine-tune their machines to achieve the desired precision.

Flexibility in material types also promotes creativity. Designers can experiment with innovative materials and applications. However, this experimentation may lead to mistakes. Striking the right balance between innovation and practicality is crucial. Exploring new materials can yield exciting products but can also stretch budgets and timelines. Embracing this aspect is essential for growth in the competitive manufacturing landscape.

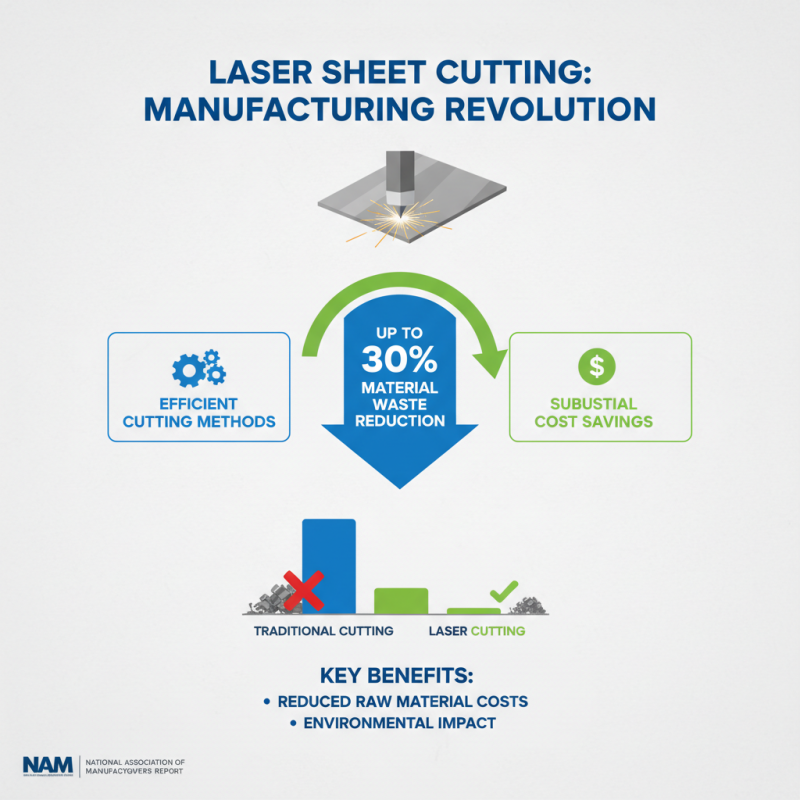

Laser sheet cutting machines have transformed modern manufacturing. They significantly reduce waste, which is a critical factor in cutting costs. According to a report by the National Association of Manufacturers, efficient cutting methods can reduce material waste by up to 30%. This reduction translates to substantial savings over time, especially in industries with high raw material costs.

The precision of laser cutting offers another advantage. It minimizes errors, which means fewer faulty products. This precision helps companies avoid the costs associated with rework and excess inventory. The American Manufacturing Association states that about 20% of manufacturing costs stem from waste and errors. By utilizing laser technology, companies can address these issues effectively.

Despite the benefits, some challenges remain. Initial investment costs can be high. Smaller manufacturers may struggle to justify these expenses. Moreover, maintenance of laser machines requires skilled personnel. Training can add to operational costs. As companies navigate these issues, the journey toward cost efficiency continues to be a balance of investment and innovation.

Laser sheet cutting machines have revolutionized modern manufacturing by offering numerous advantages that enhance production processes. One of the key benefits is their improved precision and accuracy, ensuring that cuts are clean and exact, which is critical for high-quality outputs. Additionally, these machines significantly boost efficiency and speed, allowing manufacturers to meet increasing demand without compromising on quality.

Versatility is another important aspect, as laser sheet cutting machines can work with various materials, making them suitable for diverse applications across different industries. Furthermore, they contribute to reduced waste and cost savings, optimizing resources and minimizing excess. As technology advances, the future of laser cutting machines promises even more innovative features, positioning them as essential tools for competitive manufacturing in an ever-evolving market.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.