By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

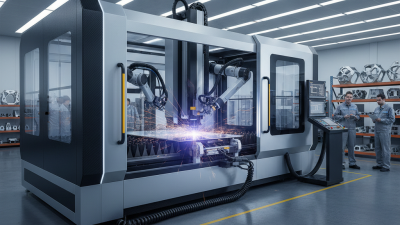

When it comes to choosing the best CNC metal laser cutting machine, several factors come into play. This decision can be daunting. Each machine offers unique features, so knowing your specific needs is essential. The right machine can significantly enhance your productivity and quality of work.

Investing in a CNC metal laser cutting machine requires careful consideration. Material type, thickness, and cutting precision are vital. These details can lead to mistakes if overlooked. You might find yourself with a machine that doesn’t quite fit your projects. Therefore, understanding your applications is crucial for making an informed choice.

Furthermore, budget constraints can influence your decision. Higher-priced machines often provide advanced features but may not be necessary for every task. It's important to weigh your options and reflect on what truly matters for your operations. Ultimately, identifying the right CNC metal laser cutting machine can propel your work to a new level of efficiency and excellence.

CNC metal laser cutting machines are transforming manufacturing industries. They utilize focused lasers to cut through metal with precision. These machines deliver a high level of accuracy and speed, making them ideal for various projects. Understanding their features helps you choose the right machine for your needs.

When selecting a CNC laser cutter, consider the material types you will work with. Not all machines handle every metal well. Stainless steel, aluminum, and brass all have different cutting requirements. Check the machine's specifications to ensure compatibility.

Tips: Always review safety features. Laser machines can be dangerous without proper precautions. Keep the working area clean and well-lit.

Another crucial aspect is the power of the laser. Higher wattage can cut thicker materials, but it can also increase costs. Reflect on how often you will need those capabilities. Sometimes, less power is sufficient for your projects.

Lastly, pay attention to customer support and maintenance options. Machines can break down, and quick solutions are essential. A reliable support system ensures your production runs smoothly.

When selecting a CNC metal laser cutting machine, consider key features. Power output is crucial, with typical ranges from 1000W to 4000W. Higher wattage means faster cutting speeds and the ability to handle thicker materials. According to industry data, machines with a 3000W power output can cut through 12mm steel efficiently.

Material compatibility is another important feature. Look for machines that can cut various metals like aluminum, stainless steel, and carbon steel. An ideal laser cutter should handle different thicknesses well. A study shows that machines with adjustable focal lengths perform better on diverse material types.

Precision is vital in laser cutting. A good CNC laser cutter should have a positioning accuracy of within 0.01mm. However, many lower-end models struggle to maintain this precision consistently. Users often find that quality drops over time, requiring frequent adjustments. This aspect needs more attention when making your choice.

| Feature | Description | Importance | Typical Value |

|---|---|---|---|

| Laser Type | Fiber, CO2, or YAG, each suited for different materials. | High | Fiber laser is commonly used for metals. |

| Cutting Area | The maximum dimensions of the material that can be cut. | Medium | Standard sizes: 1300x2500 mm to 1500x3000 mm. |

| Power Rating | Measured in watts; determines cutting speed and thickness. | High | Common ranges: 1000W to 4000W. |

| Cutting Speed | Speed of cutting material; influences production efficiency. | High | Typical: 2 m/min to 25 m/min. |

| Material Thickness | Maximum metal thickness the machine can efficiently cut. | High | Can typically cut from 0.5 mm up to 20 mm. |

| Precision | Accuracy of the cuts processed by the machine. | High | Typical precision: 0.1 mm. |

| Software Compatibility | Compatibility with CAD/CAM software for design and control. | Medium | Supports formats like DXF, PLT. |

| Price Range | Cost of the machine, which varies widely based on features. | High | Typical range: $10,000 to $300,000. |

When exploring CNC metal laser cutting technologies, understanding the types available is crucial. CO2 lasers are popular for cutting non-metal materials and thinner metals. They offer a good balance between cost and functionality. However, they may struggle with thicker materials.

Fiber lasers shine in speed and efficiency, especially for stainless steel and aluminum. They consume less power, making them appealing for long-term use. Yet, their initial investment can be a hurdle for some businesses.

Another option consists of hybrid systems, which combine both CO2 and fiber technologies. These machines provide versatility but can be complex to operate. Users may need extensive training to maximize their capabilities. This complexity could lead to mistakes, which might result in wasted materials or time. Additionally, the choice of laser source should reflect the specific needs of your operations. Each option carries its pros and cons, making it essential to carefully evaluate your production requirements.

In some instances, businesses might overlook maintenance aspects. Regular checks can prevent unexpected downtimes. Choosing a technology without understanding its upkeep can lead to frustration. Explore thoroughly and consider all your options. Seek advice when necessary. After all, the best cutting machine should align with your operational goals and capabilities. Be mindful of these factors to avoid regrettable decisions.

When assessing your workflow and material requirements for CNC metal laser cutting, it's crucial to consider both your production volume and the materials you'll use. According to a recent industry report, 45% of manufacturers prioritize cutting speed over other features. This highlights that understanding your specific needs is essential. A slower machine may suffice if your projects are small-scale and intricate. However, high-volume demands require faster, more efficient solutions.

Diverse materials also play a significant role in selecting the right machine. Some lasers perform better on thin metals, while others handle thick materials more efficiently. Research indicates that about 40% of metal fabricators encountered issues with material compatibility when using the wrong type of laser. It is important to assess your main materials—whether aluminum, stainless steel, or copper—against the machine's capabilities.

Additionally, processing time can vary significantly based on the equipment used. Some machines can reduce cutting time by up to 30% for specific applications. Yet, this speed might come at the cost of precision for detailed designs. Reflect on your production process and whether precision or speed is your priority. Exploring varied machine specifications and their impact on your specific tasks can lead to a better-informed decision that aligns with your operational goals.

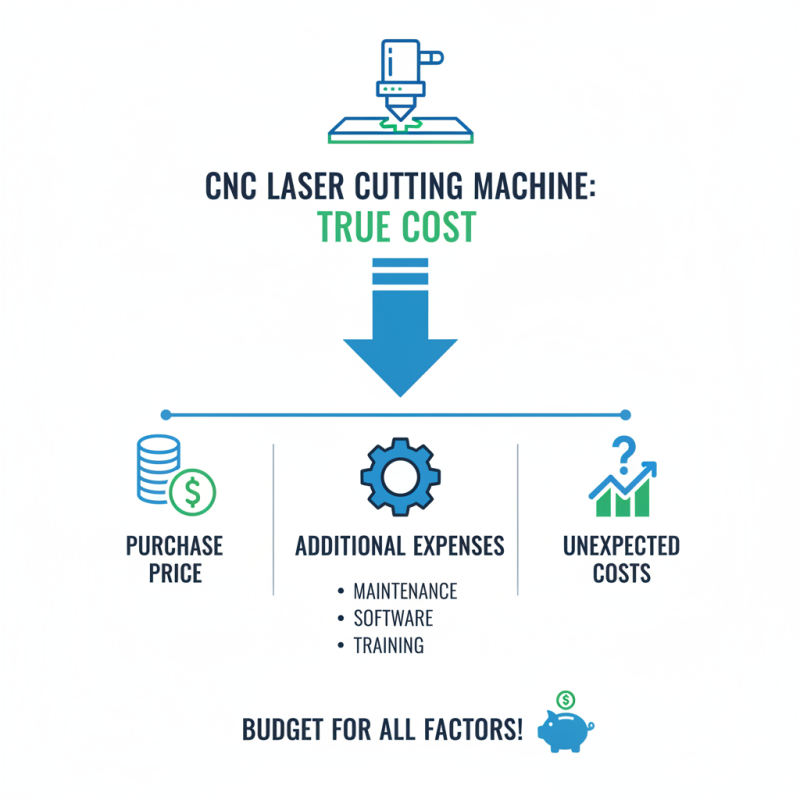

When selecting a CNC laser cutting machine, budget plays a crucial role. Many buyers often underestimate costs. It's not just about the machine's price; consider additional expenses. These include maintenance, software, and training. A good budget should account for all these factors. Unexpected costs can arise quickly.

Some may opt for entry-level machines to save money, but these often lack advanced features. They may struggle with precision and speed. Investing in a slightly more expensive model can save you time and frustration in the long run. This could lead to better quality and efficiency.

Analyze your specific needs carefully. What materials will you cut? What thickness? These factors can influence the machine's cost. A machine suitable for complex tasks will likely cost more. Always weigh your options and think long-term. A budget is not merely a number; it should align with your goals. Reflect on what you truly require before making a purchase.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.