By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

In the ever-evolving landscape of food processing and oil extraction, the role of the screw press machine has gained significant importance. These machines provide a reliable and efficient method for extracting oils from various seeds and nuts, making them a vital component in both industrial and artisanal production. Renowned industry expert Dr. Emily Thompson, a leading figure in mechanical engineering and food technology, emphasizes the impact of these machines on sustainability and efficiency, stating, "The advancement of screw press machines is revolutionizing how we extract oil, significantly reducing waste and enhancing productivity in food processing."

The versatility of screw press machines allows them to cater to a wide range of applications in the food sector, from producing cooking oils to facilitating the extraction of essential nutrients for health supplements. As consumers increasingly seek natural and sustainably sourced products, the demand for advanced screw press technologies continues to rise. This shift not only benefits producers but also aligns with global trends towards healthier eating and sustainable practices. By understanding the numerous advantages that screw press machines offer, stakeholders in the food industry can leverage these innovations to enhance their operations and meet the demands of a conscious consumer base.

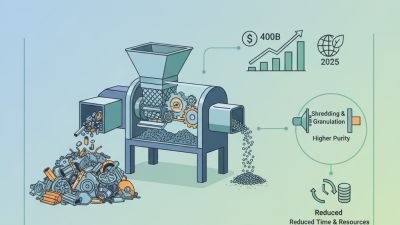

Screw press machines are an essential tool in the oil extraction and food processing industry. They operate on a simple principle: compressing materials to separate oil or juice from solids. This method utilizes mechanical force, which not only maximizes extraction efficiency but also preserves the quality of the final product. The design typically features a rotating screw that moves the raw material through a tapered chamber, thereby increasing pressure and facilitating the extraction process.

When considering a screw press machine, it's crucial to select the right model based on the type of material being processed. For instance, oilseeds such as sunflower or soybean require specific settings to achieve optimal extraction rates. Additionally, understanding the operational parameters, such as temperature and pressure, can significantly impact yield and product quality.

**Tips:** Always conduct thorough material preparation to ensure maximum oil yield. Preheating seeds can enhance extraction efficiency, and adjusting moisture content may also improve results. Regularly maintaining the machine will ensure longevity and consistent performance, ultimately benefiting your production line.

Screw press machines play a vital role in the oil extraction process, offering a range of options tailored to different types of seeds and nuts. One of the most common types is the single screw press, which utilizes a rotating screw within a cylindrical chamber to crush and extract oil from the raw material. This method is known for its simplicity and efficiency, making it a popular choice for small to medium-sized operations. The single screw press can handle a variety of oilseeds, including sunflower, sesame, and cottonseed, providing versatility for food processors.

Another significant type is the double screw press, which features two parallel screws for improved extraction efficiency. This design enables a higher yield of oil while reducing the amount of residue left in the seed. It is particularly advantageous for larger scale operations where maximizing oil yield is essential. The double screw press is capable of processing tougher seeds and nuts, including palm fruit and soybeans, which require increased pressure and heat during extraction.

In addition to single and double screw presses, specialized machines such as cold press and expeller press are designed for particular applications. Cold pressing involves extracting oil at low temperatures, preserving the oil's flavor and nutritional value, while expeller pressing employs a more mechanical method, often at higher temperatures, suitable for achieving higher oil yields efficiently. Each type of screw press machine offers distinct benefits and capabilities, allowing processors to select the best option based on their specific needs and types of materials used.

When selecting a screw press for oil extraction and food processing, there are several key features to consider that significantly impact efficiency and effectiveness. The first crucial aspect is the material of the pressing shaft and housing; high-quality stainless steel is often preferred for its durability and resistance to corrosion. Data from industry reports indicate that machines with durable components can operate continuously for extended periods without maintenance, leading to lower operational downtime. In addition, adjustable pressing temperatures can enhance oil yield, with optimal temperatures typically ranging from 50°C to 80°C for most oilseeds.

Another vital consideration is the machine's capacity and throughput. Depending on the scale of your operations, it is essential to choose a screw press that can meet both current and future production demands. For instance, a screw press with a higher extraction rate can lead to a significant increase in productivity. According to the latest market analyses, machines with higher extraction efficiencies have been found to improve production rates by up to 25%, making them a worthwhile investment for businesses aiming for growth.

Tips for choosing the right screw press include assessing the machine’s ease of cleaning and maintenance. A design that facilitates quick disassembly helps reduce cleaning time, which can be crucial in food processing settings. Additionally, consider the availability of technical support and parts, as reliable service can ensure your operations remain uninterrupted. Always review the specifications and compare reports based on extraction efficiency and machine longevity to make an informed decision that aligns with your production goals.

Screw press machines have become essential tools in the food processing industry, offering numerous advantages for oil extraction and beyond. One of the primary benefits of using screw press machines is their efficiency. These machines are designed to extract oil from various seeds and nuts with minimal waste. The continuous feeding mechanism allows for a high throughput, making them ideal for large-scale production. Additionally, the extraction process itself tends to produce higher yields compared to traditional methods, ensuring that manufacturers can maximize their output and profitability.

Another significant advantage of screw press machines is their versatility. They can efficiently process a wide range of materials, from oilseeds like sunflower and soybeans to other food products. This adaptability makes them suitable for various applications in the food processing sector. Moreover, the extraction process is generally simpler and requires less energy than other methods, promoting sustainability within the industry. With their ability to maintain the nutritional quality of the extracted oil, screw press machines contribute not only to efficiency but also to the health standards of the food products being processed.

Maintenance is critical for maximizing the efficiency of screw press machines used in oil extraction and food processing. Regular maintenance not only extends the lifespan of the equipment but also ensures optimal performance, helping to achieve higher productivity and better-quality output. Neglecting maintenance can lead to mechanical failures, decreased efficiency, and increased costs.

One important tip is to routinely check and lubricate moving parts to reduce friction and wear. Proper lubrication minimizes the risk of overheating and helps maintain consistent operation. Additionally, it is essential to clean the machine after each use. Residue from previous processes can accumulate and hinder performance, leading to contamination and spoilage in food products. A thorough cleaning routine prevents buildup and keeps the system running smoothly.

Another key aspect is to monitor the machine for unusual noises or vibrations, as these can be indicators of underlying issues. Regular inspections can catch potential problems early, allowing for timely repairs before they escalate. By adhering to these maintenance tips, operators can ensure that their screw press machines operate at peak efficiency, resulting in more effective oil extraction and enhanced processing of food products.

| Machine Model | Oil Extraction Rate (%) | Processing Capacity (kg/hr) | Power Consumption (kW) | Maintenance Frequency (months) | Typical Applications |

|---|---|---|---|---|---|

| Model A | 95 | 500 | 15 | 6 | Vegetable Oils |

| Model B | 92 | 400 | 10 | 12 | Nuts and Seeds |

| Model C | 90 | 300 | 12 | 8 | Olive Oil |

| Model D | 93 | 350 | 14 | 7 | Coconut Oil |

| Model E | 94 | 450 | 16 | 5 | Palm Oil |

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.