By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

In the fast-paced world of manufacturing, an industrial steel cutting machine plays a crucial role. These machines are designed to handle the demands of heavy steel fabrication. They ensure precision and efficiency in production lines. Choosing the right machine can greatly enhance productivity and reduce operational costs.

The market offers various types of industrial steel cutting machines, each with different features. Some are more suitable for thick steel, while others excel in speed and versatility. It's vital to assess your specific needs before making a choice. The wrong machine can lead to delays and increased waste.

Remember, not all machines are created equal. Differences in technology can impact the overall quality of the cut. Regular maintenance is necessary to prevent performance issues. Investing in a high-quality industrial steel cutting machine can yield long-term benefits. However, one must also consider budget constraints and operational goals carefully. It’s a complex decision that requires reflection and planning.

Industrial steel cutting machines play a vital role in manufacturing. They increase productivity and precision in metal fabrication. According to a recent market report, the global steel cutting machine market is projected to grow at a CAGR of 5.6% from 2021 to 2026. This growth highlights the increasing demand for efficient cutting solutions.

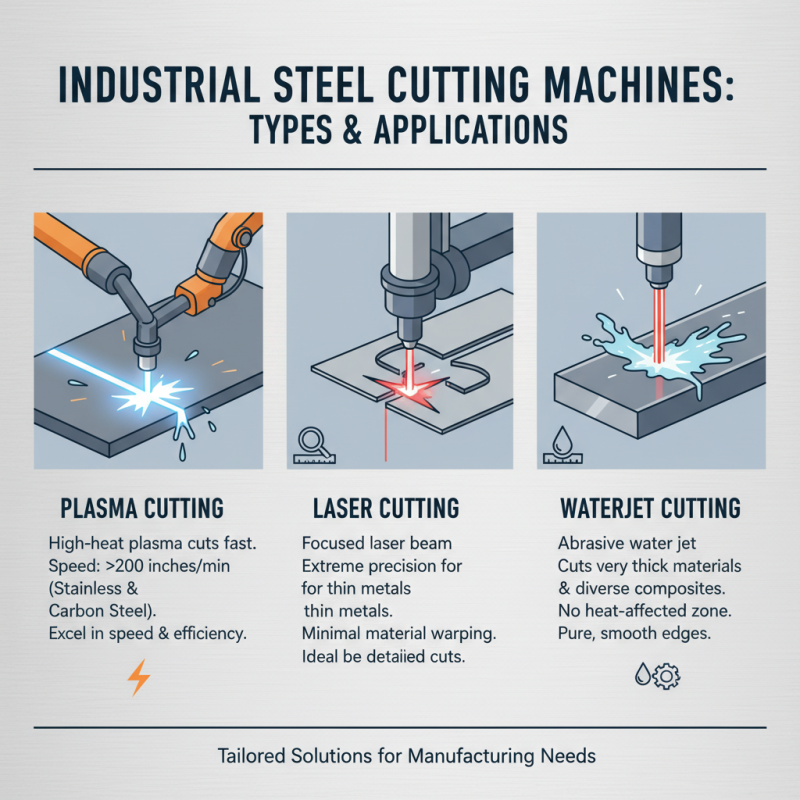

These machines come in various forms, including plasma cutters, laser cutters, and waterjet cutters. Each type offers unique advantages. For instance, laser cutting delivers high precision but may have higher operational costs. On the other hand, plasma cutting is faster but can leave a rougher edge. Manufacturers need to evaluate these factors based on their production needs.

Despite advancements, challenges remain. The technology's initial cost can be a barrier for small businesses. Maintenance of these machines can also be demanding, impacting overall efficiency. Operators must be skilled to avoid costly errors during operation. Balancing investment and productivity is crucial for success in this competitive market.

This chart represents the cutting speed (in inches per minute) of various types of industrial steel cutting machines commonly used in production environments.

When it comes to industrial steel cutting machines, understanding types is critical. Different manufacturing needs require tailored solutions. For instance, plasma cutting machines are popular in many sectors. They excel in speed and efficiency, using high-heat plasma to slice through steel with precision. According to industry reports, plasma cutters offer a cutting speed of over 200 inches per minute for stainless steel and carbon steel.

Laser cutting machines serve another niche. They provide clean cuts and are ideal for intricate designs. These machines have gained traction due to their versatility and decreasing costs. Data indicates that the global laser cutting machine market is expected to grow significantly, reflecting their rising demand in various manufacturing sectors.

Tips: Always assess your material thickness and desired finish when choosing a machine. Each type has its strengths and weaknesses. For thicker steel, oxy-fuel cutting might be the most efficient, yet may lack precision for fine details. Reflect on the specific needs of your production line. It’s essential to invest in machines that effectively match your operational goals.

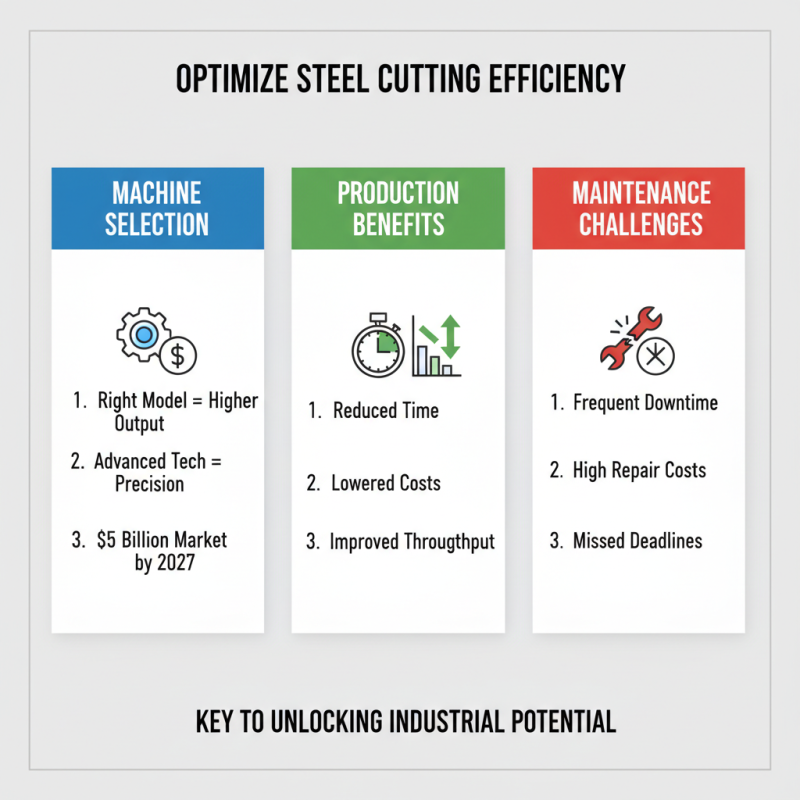

When selecting industrial steel cutting machines, several critical features should be prioritized. The type of cutting method significantly influences production efficiency. Laser cutting is known for precision but often comes with high operational costs. Plasma cutting is faster and more cost-effective for thicker materials but may sacrifice some accuracy. According to industry reports, 72% of manufacturers prioritize precision over speed when choosing equipment.

Another key feature is the machine's durability and maintenance requirements. A robust steel cutting machine can significantly reduce long-term costs. Regular maintenance is essential. Yet, many operators overlook this, leading to unexpected downtime. A study indicated that 40% of production delays stem from equipment failure. Choosing machines with user-friendly interfaces can streamline operations, reducing the learning curve for new users.

Lastly, consider the machine's versatility to handle various steel thicknesses and types. With changes in industry standards, flexibility is becoming increasingly vital. Machines that can adapt to different shapes or materials may offer a competitive edge. However, these versatile machines may come with a steeper learning curve. It's crucial to balance the desire for flexibility with the usability of the equipment.

When it comes to industrial steel cutting machines, selecting the right model is crucial for optimizing production efficiency. According to a recent industry report, the global market for cutting machinery is expected to reach over $5 billion by 2027, illustrating the demand for advanced cutting technologies. Efficient machines can significantly reduce production time and operational costs. Yet, many companies struggle to maintain their machinery, leading to frequent downtimes.

Top models in the market have features like programmable control systems and high-speed cutting capabilities. These innovations increase precision and reduce material waste. However, not all cutting machines offer the same level of reliability. Some users report issues with overheating and maintenance difficulties. Regular assessments and updates are necessary to keep machines running at peak performance.

In terms of durability, it’s essential to find balance. Machinery built for heavy-duty cutting can withstand rigorous demands, yet they also require regular care. Maintenance records show that about 20% of machine failures stem from neglect. Regular maintenance should not be overlooked. Skipping routine checks can lead to significant losses. Therefore, businesses must stay proactive to ensure their machinery remains efficient throughout its lifespan.

The landscape of steel cutting technology is rapidly evolving. Automation is becoming essential for enhancing productivity and precision. Advancements in robotic systems and AI-driven solutions are shaping the future. These technologies help reduce human error while increasing speed. The integration of smart sensors allows for real-time monitoring, ensuring optimal performance.

Tips: Regularly inspect your machines to maintain peak condition. Small adjustments can prevent major issues down the line.

Future trends indicate a shift towards more sustainable practices. Environmental concerns drive innovations in energy-efficient machines. These machines reduce waste and lower operational costs. Yet, adapting to new technologies can be challenging. Companies must invest in training to keep up with these changes.

Tips: Stay informed on industry advancements. Knowledge is power in this fast-paced environment. Engaging with industry experts can provide vital insights.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.