By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

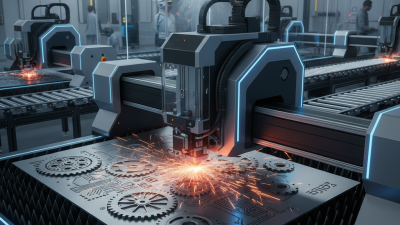

In the rapidly evolving manufacturing landscape, selecting the ideal steel sheet laser cutting machine can significantly impact productivity and cost-effectiveness. According to Dr. Henry Simmons, a renowned expert in laser cutting technologies, "The right laser cutting machine can optimize your operations, ensuring precision while reducing material wastage." As industries strive for more efficient and sustainable practices, the role of technology like steel sheet laser cutting machines becomes increasingly crucial.

When embarking on the journey to choose the best machine for your needs, it's essential to consider various factors, including laser power, cutting speed, and software compatibility. The market offers a plethora of options, making it imperative for businesses to identify their specific requirements. Investing time in understanding these elements can lead to sound decision-making and a significant return on investment.

Ultimately, the choice of a steel sheet laser cutting machine should align not only with current production demands but also with future scalability. By prioritizing the right features and capabilities, companies can harness the full potential of laser technology, driving growth and innovation in their operations.

When considering the purchase of a steel sheet laser cutting machine, it is essential to understand the various types available to ensure you choose one that aligns with your production needs. The most common types include fiber laser cutters, CO2 laser cutters, and solid-state laser cutters. Fiber laser machines are known for their efficiency and precision, making them ideal for cutting thin to medium thickness steel sheets. Their solid construction and lower operational costs offer an appealing choice for manufacturing facilities looking for performance without excessive investment.

CO2 laser cutting machines, on the other hand, are well-suited for thicker materials due to their high output and versatility. However, they may require more maintenance and can have higher operational costs than fiber lasers. Solid-state laser cutters represent another option, combining qualities of both fiber and CO2 types. They offer significant advantages in cutting speed and energy efficiency, making them a suitable choice for varied applications in metal fabrication. By understanding these distinctions, businesses can make informed decisions based on the specific requirements of their projects, leading to enhanced productivity and cost-effectiveness.

When selecting a steel sheet laser cutting machine, several key specifications must be considered to ensure it meets your operational requirements. One of the most critical factors is the laser power, typically measured in watts, which directly impacts the thickness and speed of cutting. According to industry reports, machines with laser power ranging from 1000W to 7000W are prevalent in the market, with 3000W being an optimal choice for medium thickness steel sheets (around 6-12 mm). Higher wattage lasers can significantly increase the cutting speed and efficiency, particularly for thicker materials or production environments requiring high throughput.

Another important specification is the cutting area size, as it determines the maximum dimensions of the steel sheets you can process. Machines come in various sizes, with standard cutting areas often around 1500mm x 3000mm, allowing for flexibility in handling diverse projects. Additionally, consider the type of laser resonator employed, with CO2 and fiber lasers being the most common.

Fiber lasers are rapidly gaining popularity due to their superior energy efficiency and cutting quality for reflective metals like stainless steel and aluminum. Reports suggest that fiber laser market adoption is projected to grow at a CAGR of 9.2% from 2021 to 2028, highlighting their emerging dominance in metal fabrication. Evaluating these specifications will help you choose a machine that aligns with your production capabilities and goals.

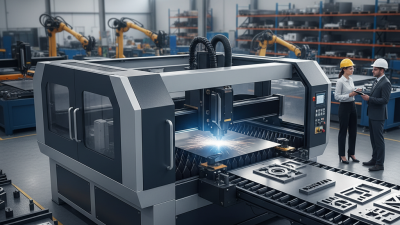

When selecting the best steel sheet laser cutting machine for your operations, understanding your specific cutting needs is paramount. One of the primary considerations is the thickness of the materials you plan to work with. Different machines have varying capabilities when it comes to cutting thickness, which can greatly influence not only the precision of your cuts but also the overall efficiency of your production process. It is essential to choose a machine that can handle the maximum thickness you anticipate, ensuring you can accommodate a wide range of projects without compromising on quality.

Equally important is the type of materials you intend to cut. Laser cutting machines can be tailored to different materials, including stainless steel, carbon steel, and alloys. Each material behaves differently under laser cutting, resulting in varying requirements for power, speed, and cooling. Understanding the specific material properties will guide you in selecting a machine that maximizes cutting quality while minimizing kerf and thermal distortion. Additionally, take into account your production volume. If you operate on a large scale, investing in a higher-capacity machine with faster cutting speeds will prove beneficial to meet your deadlines and reduce operational costs. Balancing material thickness, type, and production volume will lead you to the most suitable laser cutting solution for your needs.

When selecting a laser cutting machine, understanding the technology within is crucial. CO2 and fiber lasers represent the two primary technologies, each offering unique advantages depending on the application. Fiber lasers are increasingly favored for their efficiency in cutting thin to medium thickness metals; they boast up to 80% energy efficiency, making them both eco-friendly and cost-effective. According to a recent market analysis, fiber laser systems are projected to account for over 60% of the laser cutting machine market by 2025, reflecting their growing dominance and preference among manufacturers.

On the other hand, CO2 lasers excel in cutting thicker materials and are often the preference for non-metal applications. They deliver precise cuts and can handle a wide variety of materials, including plastics and wood—making them invaluable in diverse industries. However, CO2 systems typically require more maintenance and have a shorter lifespan than fiber systems, which could impact long-term operational costs.

**Tips:** When choosing between CO2 and fiber lasers, consider the materials you will primarily be cutting. If your work involves metals and quick operational speeds, fiber lasers might be the optimal choice. Conversely, for a broader range of material applications, a CO2 laser could serve you better. Always conduct a thorough cost-benefit analysis, focusing on energy consumption and maintenance costs in your evaluation. Additionally, engage with industry reports for the latest data on technology performance and user feedback before making a final decision.

| Feature | CO2 Laser Cutting | Fiber Laser Cutting |

|---|---|---|

| Material Compatibility | Excellent for organic materials (wood, acrylic) | Ideal for metals and thicker materials |

| Cutting Thickness | Up to 20 mm for steel | Up to 25 mm for steel |

| Speed | Slower cutting speeds | Faster cutting speeds |

| Maintenance Cost | Higher maintenance frequency | Lower maintenance frequency |

| Energy Efficiency | Less energy efficient | More energy efficient |

| Initial Cost | Generally lower | Generally higher |

| Cut Quality | Smooth edges for organic materials | High-quality cuts with minimal slag |

When considering the purchase of a steel sheet laser cutting machine, it's crucial to conduct a thorough cost analysis that encompasses not only the initial purchase price but also ongoing maintenance and operational expenses. According to a recent industry report by MarketsandMarkets, the average price of industrial laser cutting machines ranges from $50,000 to $500,000, depending on the technology and capabilities. Buyers should be prepared to allocate a substantial portion of their budget to acquire a machine that meets their production needs and material specifications.

Maintenance costs can significantly impact the overall budget. Research indicates that companies typically allocate 3-5% of the machine's initial cost annually for maintenance. This includes routine servicing, replacement of parts, and adjustments to ensure optimal performance. Additionally, operational costs such as electricity consumption, gas for cutting processes, and labor need to be factored in. The American Institute of Steel Construction states that operational costs can comprise up to 30% of the total yearly expenses for running a laser cutting operation. Therefore, understanding both the direct and indirect costs associated with procurement and ongoing operation is essential for making a sound investment in steel sheet laser cutting technology.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.