By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Choosing the right paper mill machine is a critical decision that can significantly influence the efficiency and output quality of your manufacturing process. With a plethora of options available in the market, it is essential to understand your specific needs before investing in any equipment. From the type of paper products you aim to produce to the volume required, several factors come into play that will guide you in selecting the ideal machine.

Understanding the capabilities and specifications of various paper mill machines can help you make an informed choice tailored to your production goals. This introduction explores key considerations, such as the machine's production capacity, technology, and adaptability to different paper grades. By employing a thorough assessment of your operational requirements and aligning them with the right technology, you can maximize productivity, reduce waste, and enhance the quality of your final products, ultimately leading to a successful manufacturing endeavor.

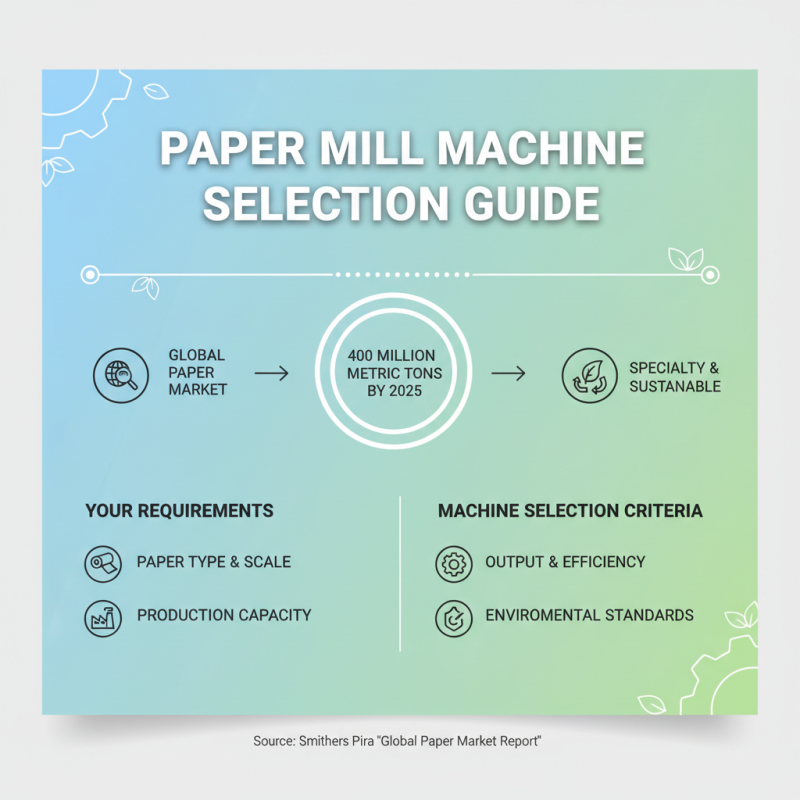

Determining the right paper mill machine requires a thorough understanding of your manufacturing requirements, as these needs vary greatly based on the type of paper produced and the scale of production. According to the "Global Paper Market Report" from Smithers Pira, the global paper industry is projected to reach over 400 million metric tons by 2025, with significant demand for specialty papers and sustainable products. This growth necessitates machinery that not only maximizes output but also aligns with environmental standards and efficiency benchmarks.

When assessing production requirements, factors such as machine speed, production capacity, and the types of paper grades must be considered. For example, producing high-quality, lightweight coated paper may require more advanced equipment with precision control features compared to basic newsprint production. Data from the "Pulp and Paper Industry Statistics" indicate that machines capable of producing up to 1,500 tons per day are becoming increasingly popular for large-scale operations, yet smaller manufacturers may opt for versatile machines designed for short runs and flexibility, emphasizing the diverse needs across this sector. Ensuring that the selected paper mill machine meets these specifications can lead to operational efficiency and improved product quality.

When selecting a paper mill machine, it’s crucial to understand the various types available and their specific functions. The most common types include the hardwood pulping machine, which processes hardwood into pulp, and the softwood pulping machine, designed for softer trees. Each machine is optimized for different raw materials, which significantly affects the pulp's quality and characteristics. The choices extend to chemical pulping machines, which use chemicals to break down wood fibers, and mechanical pulping machines, which rely on mechanical force for fiber separation. Understanding these differences helps manufacturers identify the best machine based on the desired end product.

In addition to pulping machines, manufacturers should consider paper forming machines, which shape the pulp into sheets. These machines play a vital role in determining the paper’s thickness and texture. The drying machines are equally important, as they remove moisture from the sheets, ensuring a sturdier final product. Furthermore, finishing machines are responsible for adding any desired surface treatments, enhancing printability and appearance. Each type of machine contributes uniquely to the production process, making it essential to select the right combination that aligns with specific manufacturing needs and product specifications.

Choosing the right paper mill machine for your manufacturing needs involves several critical factors. First, consider the type of paper products you intend to produce. Different machines are designed for specific types of paper, whether it’s newsprint, cardboard, or specialty papers. Analyzing your product requirements will help you narrow down the machine types best suited for your production line.

Another essential factor is the production capacity of the machine. Evaluating your current and projected output needs will guide you in selecting a machine that can handle your desired volume without compromising on quality. It’s important to assess not only the maximum capacity but also the operational efficiency and maintenance requirements of the machine, as these will impact your overall productivity.

**Tips:** Before finalizing your decision, consult with industry experts or attend trade shows to get hands-on experience with different machines. Additionally, consider the availability of spare parts and after-sales support from suppliers, as reliable service can significantly affect your operational downtime. Lastly, always compare pricing versus the features offered to ensure you get the best return on your investment.

When selecting a paper mill machine, evaluating cost-effectiveness is paramount. A well-known report from the National Paper Manufacturers Association highlights that the initial investment in machinery constitutes about 40% of the total costs in a paper manufacturing operation. This underlines the necessity of a comprehensive analysis that includes not just the purchase price but also operational efficiency, maintenance costs, and production capacity. The best approach is to calculate the total cost of ownership (TCO), which provides a clearer picture of long-term financial commitment and helps manufacturers make informed decisions.

Another critical factor is energy consumption, as energy costs account for approximately 20% of the operating expenses in a paper mill. According to the Energy Information Administration, optimizing machinery for energy efficiency can lead to significant savings. For instance, machines designed with advanced automation and energy recovery systems can reduce energy usage by up to 30%. Additionally, understanding the expected production rates and the lifecycle of the machine is essential, as machines that offer higher yields and durability can ultimately lead to better capital returns. By focusing on these aspects, manufacturers can ensure that their investment aligns with their operational requirements and long-term profitability goals.

When selecting a paper mill machine, understanding the maintenance and support options available is crucial for ensuring long-term operational efficiency. Regular maintenance schedules can help prevent unexpected downtime and costly repairs. It's beneficial to choose equipment that comes with clear maintenance guidelines, including recommended service intervals and easy access to replacement parts. Additionally, look for machines that allow for straightforward troubleshooting, as this can simplify the maintenance process and minimize disruptions to production.

Support options are equally important in the evaluation of paper mill equipment. Consider whether the manufacturer provides comprehensive training for operators and maintenance staff, as this can significantly impact the performance of the machinery. Additionally, prompt technical support from the manufacturer can greatly enhance your operational efficiency. Evaluate whether support is available through multiple channels, such as on-site visits, remote assistance, and user manuals. A manufacturer that offers robust support services, including regular check-ins and upgrades, can help ensure that your paper mill operates smoothly and adapts to changing production needs.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.