By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

In today's manufacturing landscape, choosing the right tools is crucial. An SS laser cutting machine stands out for various reasons. The global laser cutting market is projected to reach $5.59 billion by 2025, highlighting its growing importance. Laser cutting offers precision and efficiency that traditional methods cannot match.

A recent industry report indicated that 63% of manufacturers prioritize speed and accuracy. This aligns perfectly with what an SS laser cutting machine provides. Companies can cut different materials with exceptional detail, making it versatile. However, the initial investment can be a concern for smaller businesses.

Overall, the advantages of an SS laser cutting machine outweigh the drawbacks. The enhanced productivity can lead to better profit margins. Companies must reflect on their specific needs and budget before making the leap. Investing in modern technology is not just about costs; it's about future growth.

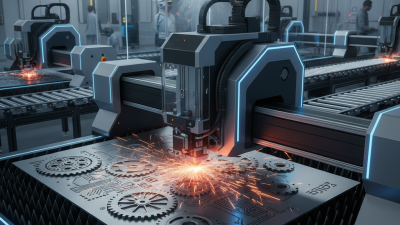

SS laser cutting machines are becoming essential in various industries. These machines use focused laser beams to cut and engrave materials like metal, wood, and plastic. Research shows that the laser cutting market is expected to reach over $6.8 billion by 2027, growing at a compound annual growth rate of around 6%. This growth highlights their increasing relevance in manufacturing processes.

One of the key benefits of SS laser cutting machines is precision. They can achieve tolerances of up to 0.1 mm. This level of accuracy reduces material waste and improves production efficiency. However, setting up these machines requires skilled operators. Training can be time-consuming and costly, which can be a barrier for smaller businesses. Nevertheless, the investment often pays off in the long run.

Moreover, these machines offer versatility. They can cut various thicknesses and materials. For instance, they can easily handle thin sheets of stainless steel while providing quality results on thick acrylic. However, users need to be wary of overheating, which can affect the final product's quality. Ensuring proper cooling systems can mitigate this issue. Balancing efficiency with potential hurdles is crucial for maximizing the benefits of SS laser cutting technology.

When considering laser cutting machines, SS models stand out. They offer precision and efficiency for various applications. These machines use advanced technology to deliver clean cuts, reducing waste significantly. The user-friendly software allows for easy integration into existing workflows, enhancing productivity.

One notable feature is their ability to cut through different materials. Stainless steel, acrylic, and wood can all be handled well. However, it’s essential to choose the right settings for each material. The learning curve can be steep for beginners. It's not just about cutting; it's about mastering the machine's capabilities.

Maintenance is another critical aspect. SS laser cutting machines require regular checks to ensure optimal performance. Dust and debris buildup can affect cutting quality. Users should develop a routine to keep the machine in top shape. Despite their advantages, there are challenges. Understanding the intricacies of the technology may take time, but it is worth the investment.

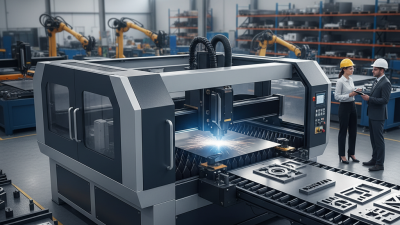

Investing in an SS laser cutting machine can enhance cost-effectiveness and efficiency in business operations. A 2023 industry report states that businesses using laser cutting technologies can improve production speed by up to 50%. This significant increase helps in meeting rising demands without heavy labor costs. Additionally, laser cutting reduces material waste by up to 30%. This not only saves money but also promotes sustainability.

The initial investment in an SS laser cutting machine may seem high. However, operational costs are significantly lower over time. A study indicated that users often recover their investment within 18 months due to increased output and efficiency. Operational downtime can be a concern. Maintenance of laser machines requires skilled technicians. Businesses must ensure they are prepared for this.

Training employees to operate these machines can take time. However, with proper training, productivity can see remarkable growth. The high precision of laser cutting means fewer errors, less rework, and overall better quality products. Such improvements can lead to better customer satisfaction and loyalty. In summary, while adopting an SS laser cutting machine presents challenges, the return on investment is encouraging.

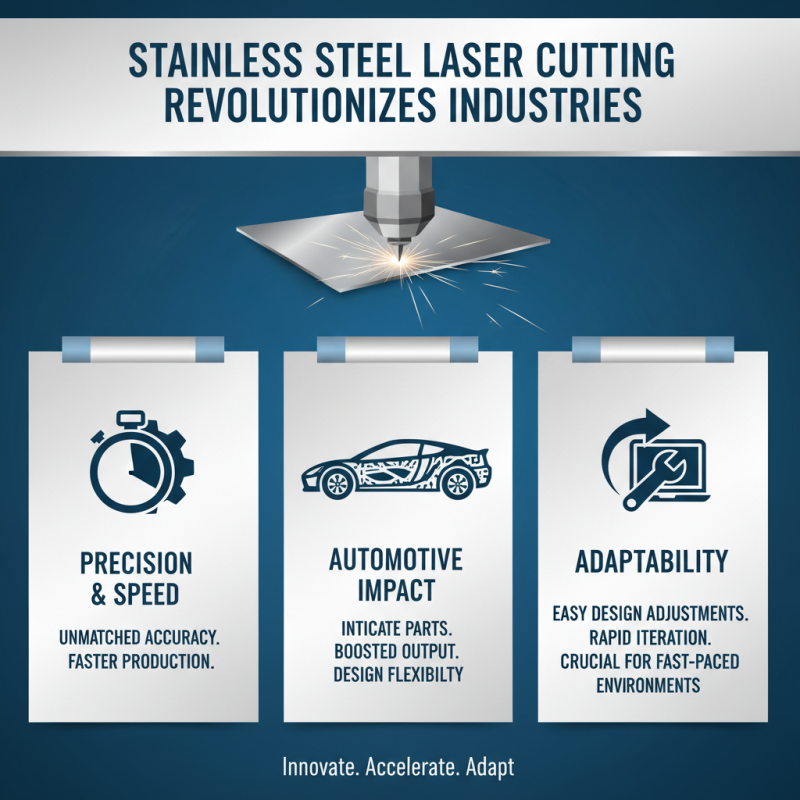

Stainless steel laser cutting machines are revolutionizing various industries. The precision and speed they offer are unmatched. In the automotive sector, for instance, intricate parts are crafted quickly. This not only boosts production but also improves design flexibility. Manufacturers can easily adjust designs without significant delays. This adaptability is crucial in such a fast-paced environment.

In the aerospace industry, the demand for precision is even higher. Lightweight components are essential for fuel efficiency. SS laser cutting provides the reliability needed for safety-critical parts. However, operators must remain vigilant. Any error in settings can lead to costly mistakes. Regular maintenance and training are necessary to ensure optimal performance.

The architectural field also benefits greatly. Custom stainless steel features enhance aesthetics and durability. From decorative panels to structural elements, the possibilities are vast. However, designers may sometimes overlook the limitations of materials. Balancing creativity and feasibility can be challenging. Engaging with fabricators early in the process can mitigate these issues.

Choosing the right SS laser cutting machine is crucial. Consider your specific business needs and the materials you work with. SS machines are versatile and can handle various thicknesses. However, the wrong choice can lead to inefficiencies and wasted resources.

Tips for selection: Evaluate the machine's capabilities based on the materials you use. Think about the thickness and composition of your materials. A machine that cuts stainless steel well might not be ideal for other materials. Additionally, assess the speed and precision you require. It’s easy to overlook these factors, but they can greatly impact productivity.

Don’t forget about maintenance and support. Regular upkeep is vital for performance. A machine that requires constant repairs can hinder your output. Look for features that simplify maintenance. Also, check customer support availability. Good support can save you from future headaches. Every detail matters, so take time to review your options.

| Factor | Description | Importance Rating (1-5) |

|---|---|---|

| Material Compatibility | Ability to cut different types of materials including stainless steel, aluminum, and plastic. | 5 |

| Cutting Precision | Level of accuracy in cutting shapes and designs, crucial for intricate projects. | 5 |

| Speed of Operation | Rate at which the machine can perform cuts, affecting overall productivity. | 4 |

| Ease of Use | User interface and controls that affect how easily operators can use the machine. | 4 |

| Maintenance Requirements | Frequency and complexity of maintenance tasks needed to keep the machine running. | 3 |

| Initial Investment | Cost of purchasing the machine compared to budget constraints and ROI potential. | 4 |

| Support and Training | Availability of technical support and training resources for operators and maintenance. | 5 |

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.