By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

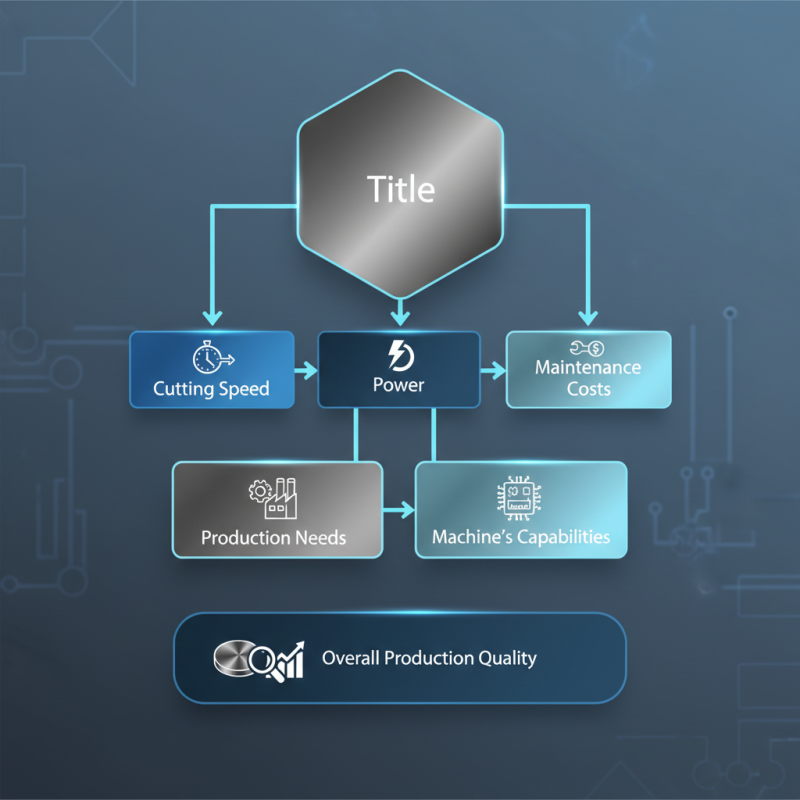

Choosing the right aluminium laser cutting machine is crucial for enhancing productivity in manufacturing. In recent years, the demand for precise metal fabrication has grown by approximately 12% annually. This increase highlights the need for efficient cutting technology in various industries, from aerospace to automotive.

Aluminium laser cutting machines offer unparalleled precision and speed, making them ideal for intricate designs. Reports indicate that laser cutting can reduce material waste by up to 30%. However, selecting the right machine requires careful consideration of several factors, including cutting speed, power, and maintenance costs. Many buyers overlook these details, potentially leading to inefficiencies and higher operational expenses down the line.

Investing in an aluminium laser cutting machine demands thorough research. Buyers must assess their production needs and the machine’s capabilities. Understanding the nuances of different models can be overwhelming. In the quest for efficiency, it’s easy to get lost in technical specifications and forget the overarching goal: improving overall production quality.

Aluminium laser cutting technology is revolutionizing various industries. It offers precision and speed, making it ideal for intricate designs. The technology uses high-powered lasers to cut through aluminium sheets. This method minimizes material waste and can produce complex shapes efficiently.

When choosing a machine, consider several factors. Understand the thickness of the aluminium you plan to cut. Different machines handle different thicknesses. A machine that cuts thin sheets may not cope well with thicker materials. Check the laser power too. Higher wattage means faster cutting, but it may also increase operational costs.

Tips: Always evaluate the machine’s duty cycle. It determines how long you can operate it continuously. Look for features like automatic feeding systems. They can enhance productivity significantly. Lastly, think about maintenance needs. A complex machine might offer great results but could be more difficult to maintain. Reflections on past choices can guide future decisions, ensuring you invest wisely in technology.

When choosing an aluminium laser cutting machine, it's essential to focus on key features that affect performance and efficiency. One critical factor is the laser power. Machines with power levels between 1000W to 2000W are standard for cutting aluminium. According to industry reports, higher wattage can cut thicker materials quickly. However, higher power may lead to excessive heat, causing distortion. Balancing power and precision is vital.

Another feature to consider is the cutting speed. Machines with faster cutting rates can enhance productivity. A report indicated that advanced machines can achieve speeds up to 30 meters per minute. Yet, very high speeds may compromise edge quality. The trade-off between speed and accuracy should be examined closely.

Additionally, a user-friendly interface is crucial for operational convenience. Some machines come with advanced software for easier programming. However, complex systems may present a steep learning curve. Operators must weigh the benefits of features against the potential need for extensive training. Each machine has its strengths and weaknesses, making careful evaluation essential before making a purchase.

When selecting an aluminium laser cutting machine, power and speed are key factors. The optimal power typically falls between 1000 to 6000 watts. This range is crucial for cutting thicknesses from 1 mm to 25 mm efficiently. According to a recent industry report, machines operating at higher power settings can cut thicker materials but may sacrifice speed. Balancing power and speed can be challenging yet essential for productivity.

Speed is another critical consideration. A cutting speed of 20 to 30 meters per minute is generally effective for aluminium. However, achieving this speed requires adequate power. A mismatch can lead to slower processing times and inferior cut quality. Some users may push their machines too hard, leading to overheating and reduced lifespan. This aspect is important to consider when evaluating long-term costs and performance.

Production rates can vary significantly among different machines. Some machines claim high speeds but may underperform under real-world conditions. It's vital to read user reviews and case studies. Understanding the actual output can provide valuable insights. Keep in mind that faster isn’t always better. Reliability and quality should never be compromised for sheer speed.

| Attribute | Value | Notes |

|---|---|---|

| Laser Power (W) | 1000 - 6000 | Higher power allows for thicker material cutting. |

| Speed (m/min) | 1 - 30 | Speed affects cutting efficiency and quality. |

| Bed Size (mm) | 1200 x 2400 | Size determines the maximum sheet you can cut. |

| Focus Lens Size (mm) | 25.4 / 35 | Smaller lens offers finer details. |

| Operating System | Windows / Linux | Compatibility with design software is critical. |

| Cooling Method | Water / Air | Water cooling is generally more effective. |

When selecting an aluminium laser cutting machine, the software and control systems play a crucial role. A user-friendly interface can significantly impact productivity. According to industry reports, 70% of operators prefer machines with intuitive software. The right software simplifies integration with existing systems, making transitions smoother.

Ease of use is often overlooked. Some software systems come with complex menus. This complexity can frustrate operators, especially new users. A recent study highlighted that 60% of errors in cutting processes stemmed from software misunderstandings. Thus, having a straightforward interface is vital.

Tip: Test the software before purchasing. Many manufacturers offer demo versions. Evaluate how easily you can navigate the controls.

Another aspect to consider is customer support for the software. Fast, effective support can reduce downtime. Reports indicate that businesses lose about $300,000 annually due to machine inactivity. A reliable support system can mitigate these losses and enhance operational efficiency.

Tip: Look for feedback on software support from current users. Their experiences can provide insight into the system's reliability.

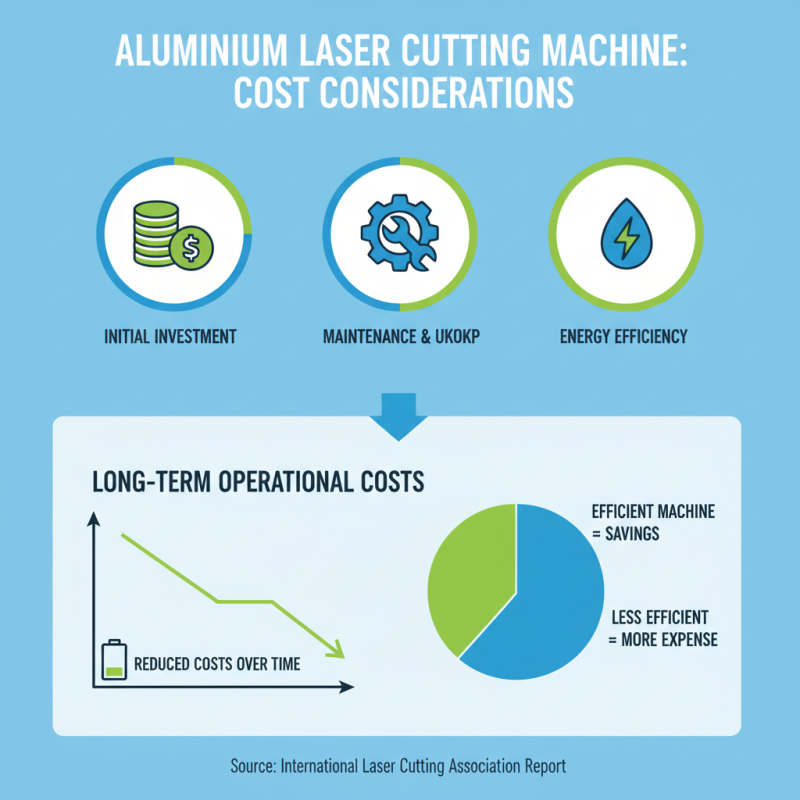

When considering the purchase of an aluminium laser cutting machine, budget plays a crucial role. The initial investment is just one piece of the puzzle. Companies must examine long-term costs too. A report by the International Laser Cutting Association suggests that maintenance and energy efficiency can heavily impact operational costs. Choosing a machine that is energy-efficient can reduce costs significantly over time.

A common mistake is underestimating the total cost of ownership. For instance, machines that require frequent repairs can lead to higher expenditures. Understanding the life span of the equipment is essential. The average lifespan of a quality laser cutting machine ranges from 10 to 15 years. This timeframe should factor into your budgeting.

Tips: Consider using cost calculators available online. They can help to estimate not only the purchasing cost but also ongoing expenses. Analyze the warranty and service agreements carefully. These can save significant amounts in unplanned repairs. Investing in training can also pay off. Well-trained operators can enhance productivity and reduce waste. Ultimately, a well-made decision today can lead to savings down the line.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.