By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Choosing the right industrial steel cutting machine can significantly impact production efficiency. A suitable machine enhances precision and reduces waste. With so many options available, making a decision can be challenging. It requires careful consideration of various factors, including specifications, intended use, and budget.

When selecting an industrial steel cutting machine, think about the materials you work with. Each machine has unique capabilities. Some excel with thick materials, while others are better for thinner sheets. The choice may come down to production volume requirements too. Will you be cutting large batches or smaller, custom orders?

Consider the technology behind these machines. Some use advanced CNC systems, while others are more manual. Take the time to reflect on the machine’s long-term value. Will it meet your future needs as you grow? Sometimes, a higher initial investment leads to far greater savings over time. Being informed helps you avoid costly mistakes.

When selecting an industrial steel cutting machine, it's important to understand the various types available. Each type has distinct features that cater to different needs. For example, plasma cutting machines are popular. They excel in speed and precision. However, operators must ensure they have the right setup for optimal performance. With plasma, materials such as stainless steel and aluminum can be cut easily.

Laser cutting machines offer another option. They provide high accuracy and smooth edges. It's crucial to consider the power of the laser. A more powerful laser can cut thicker materials. Yet, these machines can be quite expensive. The cost may be a point of concern for many buyers.

Water jet cutting represents a third alternative. This method uses a high-pressure water stream mixed with an abrasive substance. It works well for complex shapes. However, it can also produce rough edge finishes. Consideration of the end product quality is essential. Each machine type has its pros and cons. Knowing your specific cutting requirements will guide your choice effectively.

When evaluating cutting techniques, plasma, laser, and water jet are common options. Each method has distinct advantages and drawbacks. According to a recent industry report, plasma cutting can reach speeds of up to 60 inches per minute, making it suitable for thick materials. However, it can produce rough edges, which may require secondary processing.

Laser cutting offers precision with minimal material waste. This technique can achieve tolerances of ±0.001 inches. A study showed that laser cutters are particularly effective for thin metals, allowing for intricate designs. Yet, the high initial investment can be a barrier. Maintenance costs and skill requirements add to the complexity of operation.

Water jet cutting is another viable method. It utilizes high-pressure water mixed with abrasive material. The technology is versatile and generates no heat-affected zones. However, it can be slower than plasma and laser cuts. Research indicates that this technique can be up to 30% less efficient when cutting thick materials. Balancing speed, cost, and finish quality is essential. Each technique should be evaluated based on specific project needs and material types.

When selecting an industrial steel cutting machine, considering material thickness is crucial. Thicker materials require more powerful machines. A machine's capability is often defined by its cutting head and power source. Different types of metals react differently to cutting processes. For instance, carbon steel may require a different approach than stainless steel. Each metal has its own unique qualities that affect the choice of cutting technology.

Material type is equally important. Different cutting methods, such as plasma, laser, or water jet, perform best with specific materials. For example, lasers excel with thin metal sheets while plasma is advantageous for thicker plates. Reflecting on your specific needs will help refine your choices. Oversizing or undersizing a machine can lead to inefficiencies. Some machines might struggle with inconsistent cuts on specific materials. Always assess your goals before making a decision.

When selecting an industrial steel cutting machine, budget constraints are paramount. Many companies overlook the total cost of ownership (TCO). TCO includes not just the initial purchase price, but also maintenance, energy consumption, and downtime costs. A detailed report from the Manufacturing Institute highlights that operational costs can represent up to 30-40% of the total budget for manufacturing equipment.

Moreover, energy efficiency plays a critical role in TCO. For instance, machines that consume less energy can save companies substantial amounts over time. According to a recent study, optimizing energy use can reduce operational costs by around 20%. This point often gets lost in the rush to purchase.

However, the importance of long-term reliability cannot be underestimated. Machines that break down frequently lead to increased maintenance costs and production delays. A survey by the National Tooling and Machining Association indicated that about 25% of manufacturers report significant losses due to unscheduled downtime. Balancing upfront costs with potential long-term savings is crucial for making an informed decision.

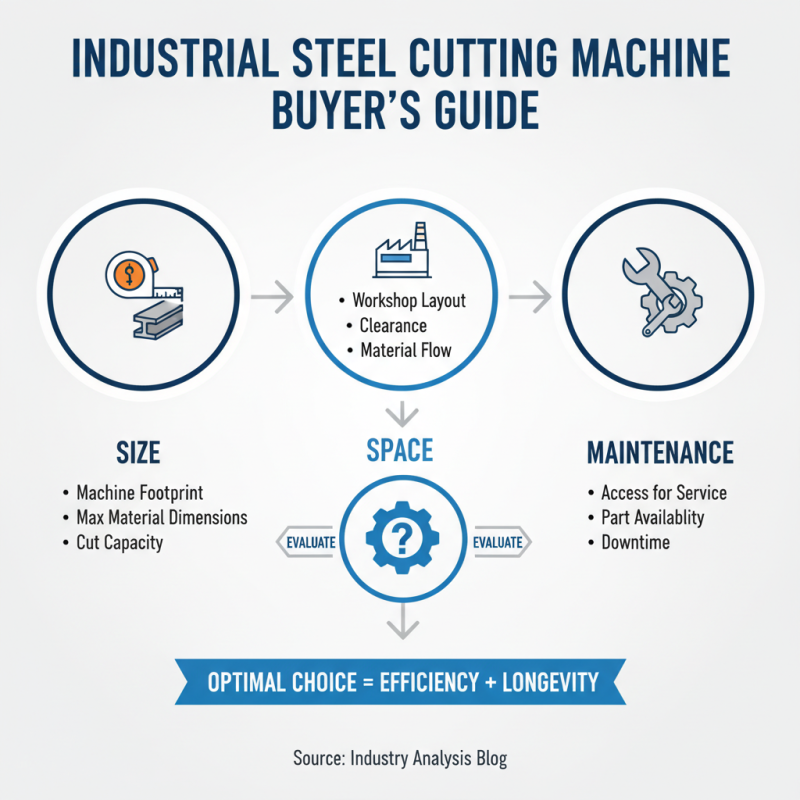

Choosing the right industrial steel cutting machine involves careful attention to size, space, and maintenance. The machine's size is crucial. It must fit well within your workspace. A compact machine might save space but may not handle larger tasks efficiently. A larger machine can perform various cuts but may require more room. Analyze your workspace dimensions before making a choice.

Space around the machine is also important. You should have enough area for operation, material handling, and maintenance access. Overcrowding can lead to accidents. Equipment should be positioned for optimal workflow and safety. Maintenance requirements can increase complexity. Some machines need frequent checks and service while others are more self-sufficient. Gauge how much time and resources you can allocate for upkeep. Consider if the ongoing maintenance aligns with your operational goals.

Choosing the wrong size can lead to wasted capacity. Consider your production needs and future growth. Sometimes, more space might be needed even if you think you have enough. Assess your options carefully, as this decision can impact your efficiency. Reflect on how well the machine will serve your long-term objectives.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.