By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

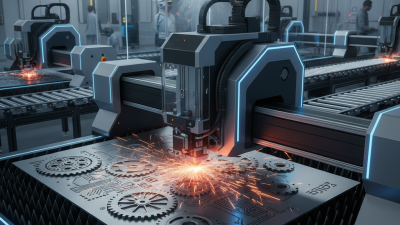

In today's competitive manufacturing landscape, the right metal plate cutting machine can make all the difference. According to industry reports, the global metal cutting machine market is expected to grow significantly, reaching over $14 billion by 2026. This growth reflects the increasing demand for precision, efficiency, and versatility in cutting operations. Businesses are recognizing the importance of investing in machinery that enhances productivity and reduces waste.

Choosing a suitable metal plate cutting machine is not a straightforward task. Various factors can affect the quality of your operations. For instance, the capabilities of different machines may vary significantly. Also, many organizations often overlook essential features. This might lead to suboptimal performance and higher operational costs. Additionally, considering each manufacturer’s support and service options is crucial yet frequently neglected.

Ultimately, recognizing the essentials of selecting a metal plate cutting machine can safeguard your investments. It helps ensure your operations run smoothly. Firms often need to reflect on their specific needs instead of going for the latest models blindly. Balancing cost, technology, and support is vital for long-term success in this dynamic industry.

Choosing the right metal plate cutting machine hinges on understanding your specific cutting needs. Different projects require different approaches. For example, think about the thickness and type of metal you often cut. A machine suited for thin sheets may not work well for thicker plates. Consider the materials you use most frequently. This knowledge will guide your decision-making process.

Tip one: Determine the maximum cutting thickness. This is crucial for efficiency. If your projects involve multiple thicknesses, look for a machine with adjustable settings.

Tip two: Assess the machine's precision. A slight variance in cutting can lead to significant issues in assembly. Ensure the machine can handle tight tolerances.

Reflect on the machine's speed as well. A faster cut might seem efficient, but it can compromise quality. No one wants to deal with rework due to poor cuts. Think about your application requirements thoroughly. A heavy-duty machine is unnecessary for light sheet metal but vital for industrial applications. Understanding your cutting needs will prevent missteps in purchasing. Balancing your requirements against the machine's capabilities is essential.

When selecting a metal plate cutting machine, understanding the different types available is crucial. Common options include plasma cutters, laser cutters, and water jet cutters. Each type has distinct features, advantages, and limitations. Plasma cutting is often favored for its speed and cost-efficiency, especially in thick materials. However, it may produce a rough edge that requires secondary finishing.

Tip 1: Consider the thickness of the materials you’ll be cutting. Plasma machines excel at thicker metals, while laser machines shine with thinner sheets. A study from the Metal Fabrication Industry Report indicates that about 45% of manufacturers prefer laser cutting for precision and smoothness.

Water jet cutting is another great option. It uses high-pressure water to cut through materials. This method is unique because it produces no heat-affected zone, making it ideal for delicate materials. However, it tends to be slower and may incur higher operational costs.

Tip 2: Evaluate your production needs. If speed is critical, plasma or laser might be optimal. For intricate designs or materials sensitive to heat, water jet cutting could be the choice. Balancing your specific requirements will ensure you select a machine that meets your operational standards.

These considerations are not exhaustive. Each shop has its unique demands and challenges. Reflecting on your current processes and future needs can help clarify the best choices.

When selecting a metal plate cutting machine, key features can greatly influence efficiency and outcome. One crucial feature is cutting speed. A machine that boasts high cutting speeds can save valuable production time. However, overly fast machines may compromise precision. It's essential to find a balance. Precision is equally important since even a small error can lead to wasted materials and increased costs.

Another vital aspect is the machine's capability to handle different materials. Many industries require versatility for various types of metal. A machine that can cut steel, aluminum, and other alloys offers more flexibility. But remember, the more materials it can handle, the more complex the settings may become. This complexity could lead to user errors if operators are not well-trained.

Finally, consider the technology used in the cutting process. CNC (Computer Numerical Control) machines provide great accuracy. Yet, they often require skilled personnel for operation and maintenance. Investing in a machine without proper training resources can be a pitfall. Ultimately, it’s about aligning the machine's features with your specific needs and the skill set of your team. Reflect on these factors before making a decision.

Investing in a metal plate cutting machine requires careful budgeting. The upfront cost can vary significantly based on features and capabilities. A report by the Fabricators & Manufacturers Association indicates that the price range can be from $10,000 to over $100,000. This wide range can be confusing for buyers.

Consider maintenance costs as well. They can add up quickly. Routine checks and part replacements should be included in your budget. Industry reports show that maintenance can represent about 10-15% of the initial cost annually. You might save money upfront but pay later.

Think about production demands too. A machine that fits your current needs might fall short as your business grows. This could lead to unexpected expenses. Industry analysis suggests that companies often under-budget equipment upgrades. Reflect on your long-term goals when allocating funds. Balancing initial costs with future requirements is crucial for success in metal plate cutting.

When investing in a metal plate cutting machine, maintenance is crucial for optimal performance. Regular servicing helps prevent breakdowns and extends the equipment's lifespan. According to a report by the Fabricators & Manufacturers Association, nearly 30% of maintenance costs stem from unscheduled downtimes. Proactive maintenance can mitigate these costs significantly.

Support services also play a pivotal role. Regular training sessions for operators can enhance efficiency and reduce mistakes. In industries where precision is vital, a simple error can lead to costly waste. A survey indicates that 20% of manufacturers witness quality issues from operator negligence. Proper training minimizes this risk.

Finding a reliable service provider is vital. Not all service contracts offer the same benefits. You may encounter hidden fees or limited support hours. Evaluate service agreements carefully. Ensure they align with your operational demands and maintenance routines. Remember, long-term costs often outweigh initial savings in contracts with poor support.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.