By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Granulating machines play a crucial role in various industries, from pharmaceuticals to plastics. According to a recent report by MarketsandMarkets, the global granulation equipment market is projected to grow significantly, reaching USD 7.2 billion by 2026. This remarkable expansion highlights the increasing demand for efficient production processes.

The efficiency of a granulating machine directly impacts production output. A well-designed granulator can enhance particle size distribution, reduce energy consumption, and improve product quality. Various factors influence the choice of granulating machines, including material properties and desired end characteristics. However, selecting the right equipment is not always straightforward. Many users face challenges in balancing production speed and quality.

Frequent maintenance is often overlooked. Ignoring it can lead to inefficiencies and increased downtime. It’s essential to have a clear understanding of your specific needs and the machine's capabilities. Pay attention to the granulating process; minor adjustments can make a significant difference. Ultimately, knowing the key factors related to granulating machines is crucial for optimizing production efficiency and ensuring long-term success.

Granulating machines play a crucial role in various industries. They convert raw materials into granules, which are easier to handle. This process often involves several steps, from mixing the ingredients to agglomerating them into larger particles.

The functionality of these machines can vary widely. Some may use wet granulation, while others rely on dry methods. The choice depends on the material properties and the desired end product. For instance, wet granulation can create more uniform granules. However, this method may complicate the drying process. Understanding these differences is essential for optimizing production.

In practice, not all granulating machines operate flawlessly. Sometimes, the size of the granules may not meet specifications. Operators need to adjust parameters carefully to achieve the best results. Regular maintenance is also key. Neglecting these aspects can lead to inefficiencies and increased costs. Reflecting on these challenges can improve overall production efficiency.

| Key Feature | Description |

|---|---|

| Definition | Granulating machines are used to process powder materials into granules, which improves flowability and reduces dust. |

| Functionality | They primarily work by agglomerating fine particles through moisture, heat, or binder addition. |

| Types | Common types include high-shear granulators, fluidized bed granulators, and roll compacters. |

| Applications | Widely used in pharmaceuticals, food, and chemical industries for precise granulation. |

| Efficiency | Enhances production efficiency by reducing the processing time and increasing yield. |

| Size Control | Integrates screens and classifiers to achieve uniform granule size. |

| Energy Consumption | Modern machines optimize energy use with advanced controls and design. |

| Maintenance | Requires regular cleaning and preventive maintenance to ensure optimal performance. |

| Regulatory Compliance | Must adhere to industry regulations, particularly in pharmaceuticals and food production. |

| Innovations | Advancements in technology such as automation and better material handling have emerged. |

Granulation is vital in industrial production processes. It transforms fine powders into granules, improving flowability and handling. This process is essential for many industries, from pharmaceuticals to food production. Without proper granulation, the efficiency of production can drop significantly.

Tips: Keep your granulation equipment clean. Dust and residue can affect the quality of granules. Regular maintenance will ensure optimal performance and prolong equipment life.

The granulation process also aids in product uniformity. Consistent particle size leads to better mixing and easier processing. However, achieving perfect granules is not always straightforward. Operators may face issues with moisture levels or binder integration. These challenges require constant monitoring and adjustments.

Tips: Monitor humidity levels closely. Too much moisture can lead to clumping. Experiment with binder ratios to find the best combination for your materials. Remember, there is always room for improvement.

When selecting granulating machines, certain key features can significantly enhance production efficiency. One important aspect is the machine's throughput capacity. According to industry reports, machines with a higher throughput can reduce processing time by up to 30%. This can lead to remarkable savings in labor and energy costs, crucial for large-scale operations.

Another vital feature is the granule size control. Opt for machines that provide precise control over granule sizes. This can ensure consistent product quality. A study from the American Manufacturing Association noted that a 1 mm variation in granule size could lead to a 15% increase in product rejection rates.

Tip: Regularly assess your production needs. Adjust machine settings to optimize performance based on material type and desired granule size.

Ease of maintenance is another consideration. Machines that require minimal downtime will keep production lines running smoothly. It's worth noting that maintenance can account for up to 20% of operational costs.

Tip: Schedule routine inspections and keep a log of repairs. This can prevent unexpected breakdowns that disrupt workflow.

Incorporating these features will not only enhance production efficiency but also improve overall product quality. Always weigh the machine's capabilities against your specific manufacturing requirements to make informed decisions.

Granulating machines play a vital role in various industries. They transform raw materials into granules, improving process efficiency. There are several types of granulating machines. Each has unique features and applications.

Roller compactors are common in pharmaceuticals. They compress powders into sheets, which are then granulated. This method often results in high-quality granules. Consider space requirements, as these machines can be large. Ensure your setup can accommodate them.

Another type is the high-shear granulator. It mixes powders with a binder to form granules. This machine is versatile and can handle a range of materials. However, operators should be trained effectively. Incorrect use can lead to inconsistent granule sizes.

Tips: Always perform regular maintenance on your granulating machines. This prevents breakdowns and increases longevity. Also, ensure you're familiar with the operating parameters specific to your material. Misjudgments can lead to waste and inefficiency. Each application may require different settings. Take time to experiment and find the ideal conditions for your production needs.

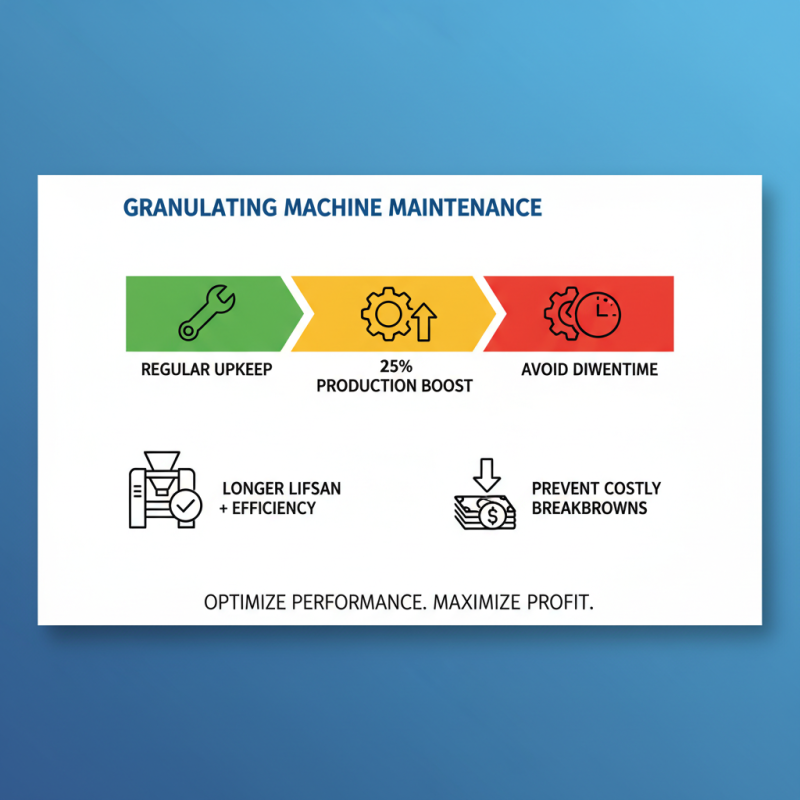

Maintaining granulating machines is crucial for optimizing their performance. Regular maintenance can lead to longer lifespan and better efficiency. According to industry reports, proper upkeep can improve production rates by 25%. Neglecting maintenance can result in severe mechanical issues, leading to unexpected downtime.

Inspecting components like blades, screens, and motors weekly is vital. Worn-out blades can reduce granulation quality. Monthly lubrication of moving parts keeps machinery running smoothly. Regular cleaning prevents material build-up, which can affect output. Data shows that insufficient cleaning can decrease efficiency by up to 15%.

Training personnel on operational best practices is often overlooked. Employees should be aware of machine limits and proper operating techniques. Proper training can prevent human errors that may cause costly damage. Remember, even small oversights can lead to larger problems down the road. Implementing a structured maintenance schedule helps in identifying potential issues early on. This isn't just about upkeep; it’s about enhancing productivity and efficiency.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.