By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

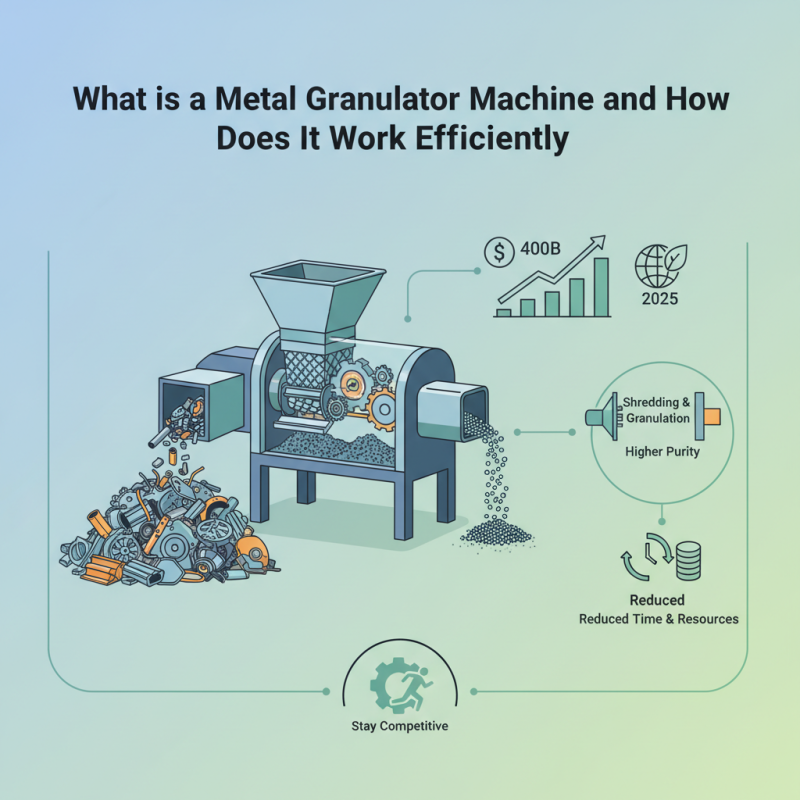

In the ever-evolving landscape of metal recycling, the metal granulator machine has emerged as a pivotal tool for enhancing efficiency and productivity in the industry. According to a recent report by Materials Recycling World, the global market for metal recycling is projected to reach $400 billion by 2025, driven by increasing awareness of sustainable practices and the growing demand for recycled metals. This evident shift underscores the importance of advanced processing technologies such as metal granulators, which not only improve scrap metal processing but also minimize environmental impact.

Industry expert Dr. Jenna McMillan, a leading authority on recycling technologies, asserts, "The innovation behind metal granulator machines significantly reduces the time and resources needed to convert scrap metal into valuable materials, thereby revolutionizing the recycling process." These machines work by finely shredding and granulating metal waste, allowing for higher purity and quality in the final product. As the demand for recycled metals continues to surge, integrating metal granulator machines into recycling operations is essential for companies aiming to stay competitive in a fast-growing market.

A metal granulator machine is a specialized piece of equipment designed to process and reduce metal waste into smaller, manageable pieces, known as granules. This type of machinery is crucial within recycling facilities where efficient materials recovery is necessary. Typically, metal granulator machines utilize a combination of cutting, shredding, and grinding mechanisms to break down various types of metal, including aluminum, copper, and steel, into uniform sizes that can be further processed or sold.

The operation of a metal granulator machine involves several steps. Initially, large metal scraps or components are fed into the machine, where rotating blades or hammers come into play. These components exert significant force, breaking the metal down through impact and shear forces. Once reduced to the desired size, the metal granules are separated from non-metallic contaminants using screening processes or air separation systems. This ensures that the final product is clean and ready for the next stage of processing or recycling, allowing facilities to contribute effectively to sustainability efforts by reducing waste and promoting resource recovery.

A metal granulator machine is a critical piece of equipment that helps in the recycling and processing of metal materials, ensuring efficient separation and reduction of scrap metal into smaller granules. The efficacy and reliability of these machines largely stem from their key components, each of which plays a vital role in the overall operation.

At the core of a metal granulator machine is the cutting system, which typically features sharp blades made from high-strength steel. These blades are designed to handle various types of metal and can cut through thick scrap efficiently, often achieving maximum output with minimal downtime. According to industry reports, the cutting efficiency can reach upwards of 95%, leading to significant reductions in waste material. Furthermore, the motor and drive system must be robust enough to handle the stresses of the cutting process, ensuring consistent performance while optimizing energy consumption. It is crucial for manufacturers to select motors that not only deliver high horsepower but also maintain operational efficiency, thereby reducing energy costs by up to 20%.

Another essential component is the separation system, which includes advanced technological features such as magnetic separators and air classifiers. These systems work in tandem to effectively sort out different metal types and eliminate non-metal contaminants. Industry standards indicate that these separation systems can operate with an efficiency rate exceeding 90%, enhancing the purity of recycled metal and increasing its market value. The combination of these components in a metal granulator machine creates a streamlined recycling process, contributing to sustainability in the metal industry while maximizing profitability for operators.

The working principle of metal granulation involves a systematic process that transforms large metal scraps into smaller granules, facilitating recycling and repurposing. Initially, the metal waste is fed into the granulator, where it is subjected to mechanical force through sharp blades. According to a report from Research and Markets, the global metal recycling market is projected to reach $500 billion by 2025, highlighting the essential role of efficient granulation in supporting this growth.

Once in the granulator, the metal undergoes size reduction through a combination of shearing, crushing, and grinding. This is powered by an electric motor that drives the blades at high speeds. The granulated metal is then screened to ensure uniform particle size, which is crucial for further processing. A study published by the Bureau of International Recycling indicates that smaller granules can increase recovery rates of precious metals by up to 98%, demonstrating the efficiency of the granulation process.

Moreover, the operation of metal granulator machines is designed to optimize energy consumption while maximizing output. Advanced technologies, such as variable speed drives and automated sorting features, enable better control over the granulation process. This efficiency is critical in an industry that relies heavily on energy resources, as highlighted in the International Energy Agency's report on industrial energy use, which states that optimizing machinery can significantly reduce operational costs while supporting sustainability initiatives in metal recycling practices.

Metal granulator machines play a pivotal role in recycling and waste management processes by efficiently shredding and granulating metal materials. One of the primary benefits of using such machines is their ability to significantly enhance the efficiency of metal recovery. By reducing metal scraps into smaller, manageable pieces, these machines facilitate easier sorting and processing, which ultimately leads to higher yield rates. This improved efficiency not only conserves energy but also minimizes the overall operational costs associated with metal recycling.

Additionally, metal granulator machines contribute to a more sustainable environment. By enabling the recycling of metals, they help reduce the demand for virgin raw materials, which can lead to lower environmental degradation. Moreover, the process of granulation helps to separate different types of metals, making it easier to recycle alloys and other mixed materials. This separation not only enhances the quality of the recycled metal but also opens up opportunities for reusing materials that would otherwise end up in landfills. In essence, the use of metal granulator machines promotes a more circular economy, benefiting both industry stakeholders and the planet.

A metal granulator machine is an essential piece of equipment used for processing various types of metal waste, resulting in smaller, manageable granules. To ensure the machine operates efficiently, regular maintenance and proper handling are crucial. One of the first tips for efficient operation is to keep the granulator clean and well-lubricated. Regularly inspect the machine for any build-up of metal shavings, which can decrease performance and impact the quality of the granules produced.

Additionally, always feed the machine with appropriately sized materials. Oversized pieces can cause blockages and strain on the motor, leading to reduced efficiency and increased wear. Operators should also monitor the machine’s operating temperatures and noise levels. Unusual sounds may indicate mechanical issues that need immediate attention, while excessive heat can signify lubrication problems or overloading. By adhering to these maintenance tips, operators can extend the lifespan of the machine and ensure consistent performance in metal processing.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.