By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

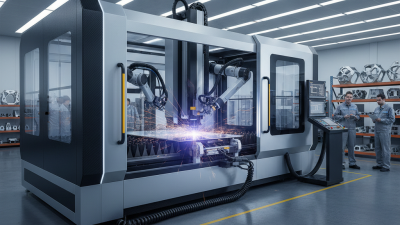

A sheet metal laser cutting machine is a vital tool in modern manufacturing. It uses focused laser beams to cut through various materials with precision. This machine is widely used in industries like automotive, aerospace, and electronics.

In many factories, the efficiency of a sheet metal laser cutting machine is impressive. It allows for intricate designs and clean edges, which are crucial for product quality. Operators must still pay attention to detail. Even a small error in settings can lead to waste and increased costs.

The technology is evolving rapidly. New features emerge, yet the basics remain the same. Mastering the use of a sheet metal laser cutting machine requires practice and skill. Learning from mistakes is part of the process. Embracing this technology can transform production processes but demands careful handling and constant adaptation.

A sheet metal laser cutting machine is a powerful tool used in manufacturing. It uses focused laser beams to cut through various types of metal sheets with precision. The machine is versatile and can handle different thicknesses and materials. This capability makes it a favorite in industries such as automotive and aerospace.

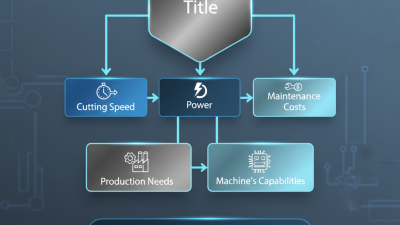

One key feature of these machines is their speed. They can cut intricate designs quickly without causing distortion. Operators must regularly check the calibration to maintain accuracy. A small misalignment can lead to costly errors. It’s crucial to keep the machine clean and free of debris, as this can affect performance.

**Tips:** Always use quality metal sheets to get the best results. Be mindful of laser settings to prevent burning or warping. Consider running test cuts on scrap material when trying new designs. This practice can save time and resources. Regular maintenance is vital to keep the machine running smoothly. Flaws can creep up if not addressed, leading to inefficiencies.

Laser cutting machines have transformed the sheet metal fabrication industry. At the core of these machines are several key components that work synergistically. The laser source generates a focused beam of high-energy light. This beam is directed through a series of optics to achieve precision cutting. According to industry reports, more than 50% of manufacturers now employ laser cutting technology for its efficiency and accuracy.

Another essential component is the cutting head. It not only focuses the laser but also controls the flow of gas used during cutting. This helps in removing molten material effectively. The integrated CNC system allows for intricate designs. However, the calibration of these systems is crucial and often overlooked. A misalignment of just a few microns can lead to significant errors in the final product.

The motion control system completes the setup. It dictates the speed and movement of the cutting head across the material. Recent data highlights that companies optimizing these systems can improve production rates by up to 30%. Yet, many still face challenges in adapting to rapid technology changes. Awareness and training are often inadequate, leading to potential inefficiencies. Understanding these components and their interactions can significantly enhance performance in sheet metal cutting applications.

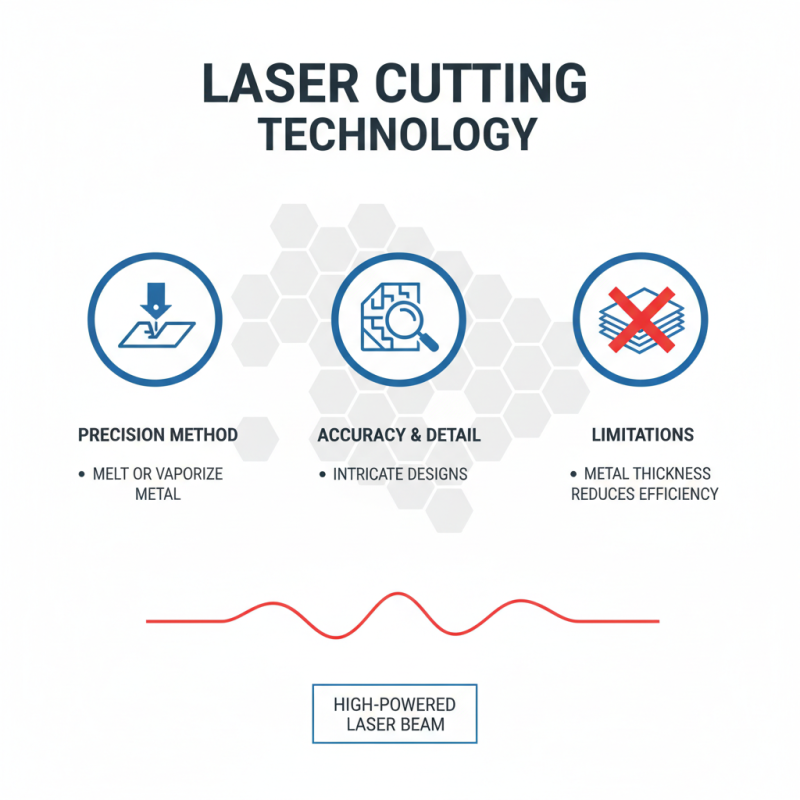

Laser cutting technology is a precise method used to cut sheet metal. A laser cutting machine focuses a high-powered laser on the material. This intense beam generates enough heat to melt or vaporize the metal. The accuracy of the process is remarkable. It can achieve intricate designs and fine details. However, there are sometimes limitations. The thickness of the metal can reduce cutting efficiency.

The machine's operation involves several key components. A control system regulates the laser's power and path. Mirrors direct the beam onto the material. An assist gas, like oxygen or nitrogen, often helps improve the cutting process. This gas can influence the cut edge quality. While many benefits exist, there can be issues. Improper settings may lead to uneven cuts. During operation, the machine must be monitored closely to avoid mistakes.

Overall, laser cutting is a popular choice in various industries. It offers high precision and speed. However, it requires careful attention to detail. Operators must constantly evaluate settings and maintain the equipment. Those involved should continually seek improvement and better practices. Each project brings unique challenges, making reflection essential.

Sheet metal laser cutting technology has transformed various industries. It provides precision and versatility, making it suitable for multiple applications. In the automotive sector, this technology is used to create intricate parts. Manufacturers rely on laser cutting for components like brackets and chassis parts. The ability to cut complex shapes helps reduce waste and improve efficiency.

In the electronics industry, laser cutting is crucial for fabricating enclosures and circuit boards. The precision of laser systems ensures that parts fit together seamlessly. However, not all projects proceed smoothly. Issues like material distortion or unexpected cutting speeds can arise. These challenges prompt engineers to refine their processes continually.

The construction field also benefits from laser cutting. Steel beams and frames are precisely cut to meet project specifications. This technology allows for quick modifications and adaptations as needed. Mistakes can sometimes lead to costly delays, reminding us of the need for careful planning. Overall, while sheet metal laser cutting machines elevate productivity, they also encourage constant improvement in technique and precision.

Laser cutting has revolutionized sheet metal fabrication. This technology offers precision and efficiency like no other. Unlike traditional methods, laser cutting uses a focused beam of light to slice through metals. This results in clean edges and intricate designs that are hard to achieve otherwise.

One major advantage of laser cutting is its speed. The process is quick, reducing production time significantly. Additionally, there is little need for extensive setup. The machine can be programmed to handle various designs and materials. There's also minimal material waste, which is beneficial for cost-effectiveness.

However, there are challenges. Training is essential for operators. Mistakes can lead to defective parts, wasting both time and resources. Moreover, the initial investment in laser cutting technology can be high. Companies often need to weigh long-term benefits against upfront costs. As with all advanced technologies, reflection on efficiency and sustainability remains key.

| Feature | Description |

|---|---|

| Cutting Technology | Uses high-powered laser beams to cut through sheet metal |

| Material Compatibility | Works with various metals like stainless steel, aluminum, brass, and copper |

| Precision | Provides high precision and fine cutting with minimal kerf width |

| Speed | Faster than traditional cutting methods, boosting production rates |

| Cost Efficiency | Reduces waste material and operational costs |

| Flexibility | Easily adapts to different designs and shapes due to programmable CNC technology |

| Safety | Low risk of accidents compared to manual cutting methods |

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.