By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

In recent years, the demand for sustainable and eco-friendly products has surged, leading many individuals and businesses to explore innovative ways to contribute to environmental conservation. One such method is the production of paper pulp, which serves as a fundamental raw material for making paper products. The advent of small paper pulp making machines has made it easier than ever for both home-based entrepreneurs and small-scale business owners to create their own paper pulp efficiently and sustainably. These compact machines not only help reduce waste by recycling old paper but also empower users to produce high-quality pulp right in their own spaces.

The versatility of small paper pulp making machines makes them an attractive investment for various applications, from crafting unique handmade papers to supplying material for small businesses. By integrating these machines into their workflow, users can experience a cost-effective solution that promotes sustainability while satisfying the growing consumer preference for recycled products. This article explores the top 10 small paper pulp making machines available on the market today, evaluating their features, efficiency, and suitability for different needs. Whether you are looking to start a new venture or simply want to engage in an eco-friendly hobby, finding the right small paper pulp making machine can significantly enhance your productivity and creative potential.

Small paper pulp making machines have become increasingly popular among both home users and small businesses. These machines offer an efficient way to create paper pulp from various raw materials, allowing users to produce their own paper products sustainably. By transforming waste paper or agricultural residues into usable pulp, these machines not only help in recycling efforts but also contribute to eco-friendly production practices.

When selecting a small paper pulp making machine, consider the production capacity and the types of materials you plan to use. Some machines are designed to handle specific inputs, while others offer versatility to work with a range of organic waste. Additionally, evaluate the ease of use and maintenance requirements of the machine, as these factors significantly impact long-term satisfaction and efficiency.

Tips: Always ensure that the machine you choose has safety features to prevent accidents during operation. It’s also beneficial to invest in a machine with a warranty or customer support service to assist with any technical issues you may encounter. Regular cleaning and maintenance will help prolong the life of your machine and ensure consistent quality in your pulp output.

| Model | Production Capacity (kg/hour) | Power Requirement (kW) | Dimensions (L x W x H cm) | Weight (kg) | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 100 | 1.5 | 150 x 70 x 100 | 70 | $500 - $700 |

| Model B | 150 | 2 | 160 x 75 x 110 | 85 | $600 - $800 |

| Model C | 200 | 2.5 | 170 x 80 x 120 | 90 | $700 - $900 |

| Model D | 250 | 3 | 180 x 85 x 130 | 100 | $800 - $1,000 |

| Model E | 300 | 3.5 | 190 x 90 x 135 | 110 | $900 - $1,200 |

| Model F | 350 | 4 | 200 x 95 x 140 | 120 | $1,000 - $1,500 |

| Model G | 400 | 4.5 | 210 x 100 x 145 | 130 | $1,200 - $1,800 |

| Model H | 450 | 5 | 220 x 105 x 150 | 140 | $1,500 - $2,000 |

| Model I | 500 | 5.5 | 230 x 110 x 155 | 150 | $1,800 - $2,500 |

| Model J | 550 | 6 | 240 x 115 x 160 | 160 | $2,000 - $3,000 |

When selecting a small paper pulp making machine, it's essential to focus on several key features that directly impact efficiency and usability. First, consider the machine's capacity, as it determines how much pulp can be produced in one cycle. For home users, a smaller capacity may suffice, while businesses may require larger machines capable of handling higher volumes. Look for machines with adjustable settings to accommodate different types of paper and pulp, as this versatility can enhance your production methods.

Another crucial aspect is the machine’s ease of use and maintenance. A user-friendly interface can make a significant difference, especially for those new to pulp making. Additionally, consider the maintenance requirements—models that are easier to clean and service can save time and extend the life of your machine. Power consumption is also a significant factor; opting for energy-efficient options can lead to cost savings over time.

Tips: Always check customer reviews and testimonials to gauge the reliability and performance of the machine you are considering. If possible, seek out demonstrations or trials to ensure the machine meets your needs before making a purchase. Lastly, don't forget to compare warranty options, as a good warranty can provide peace of mind and protect your investment in the long run.

When considering the purchase of a small paper pulp making machine, both home and business users benefit from understanding the efficiency and functionality these machines offer. According to recent industry reports, the global paper recycling market is expected to reach 400 million metric tons by 2025, driven by rising environmental awareness and the need for sustainable manufacturing practices. This growing demand underscores the importance of choosing the right equipment to produce high-quality pulp efficiently.

In our review of the top ten small paper pulp making machines, we emphasize their scalability and ease of use, which make them ideal for both artisanal and small-scale commercial operations. For instance, machines that can handle varying fiber inputs have gained popularity due to their versatility, enabling users to produce different types of paper products without significant adjustments. Furthermore, the average energy consumption for efficient models has decreased by up to 25% over the past few years, enhancing their sustainability credentials. With innovative features such as automated pulp testing and consistency monitoring, these machines provide not only cost savings but also contribute to producing superior paper pulp that meets industry standards.

When considering small paper pulp making machines for home and business use, price and performance should be at the forefront of your decision-making process. For home use, the ideal machine should balance affordability with efficiency, enabling users to produce quality paper pulp without significant investment.

Many machines in this category range in price, typically from a few hundred to a couple of thousand dollars, depending on their features. The lower end of the spectrum often includes simpler models that are user-friendly and perfect for small-scale operations, while higher-end options may offer advanced technology and larger production capacities.

Performance is equally crucial, particularly for users looking to maximize productivity in their paper-making endeavors. Machines designed for home use should be capable of processing various materials, such as recycled paper and organic fibers, to create pulp suitable for different types of paper products. The ability to control the consistency and texture of the pulp can significantly affect the final product's quality.

Evaluating machines based on their energy consumption and maintenance requirements is also vital, as these factors directly impact long-term usability and cost-effectiveness. Whether for hobbyists or small businesses, making an informed choice involves balancing price, functionality, and the machine’s capabilities to meet specific needs in paper production.

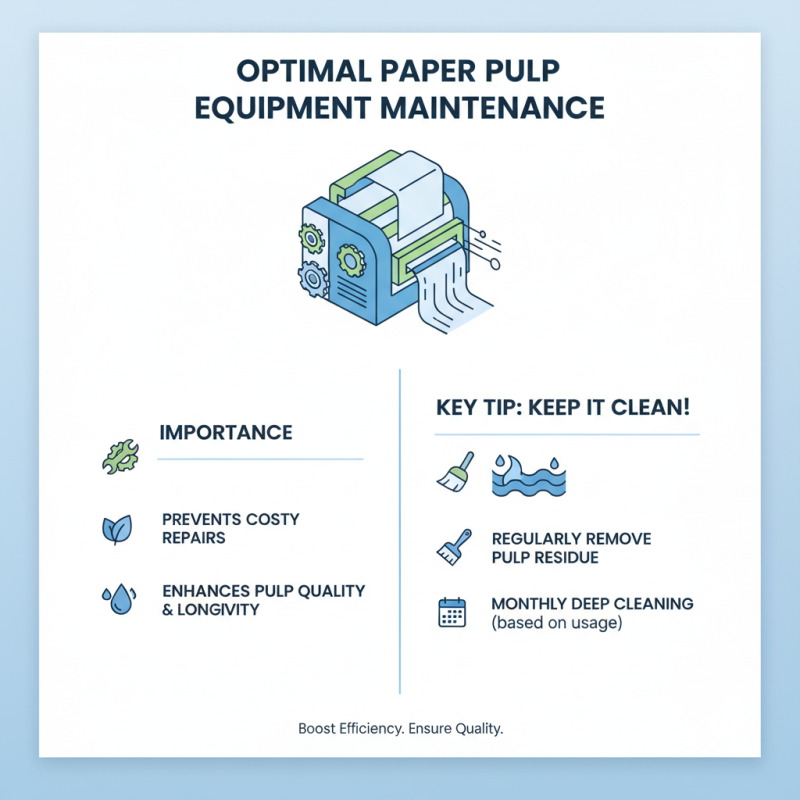

Maintaining paper pulp making equipment is crucial for ensuring optimal performance and longevity. Regular maintenance not only helps in preventing costly repairs but also enhances the quality of the paper pulp produced. One of the primary tips is to keep the machine clean. Regularly removing pulp residue and debris from the machine will prevent build-up that can lead to malfunctions. It’s advisable to schedule a deep cleaning at least once a month, depending on usage frequency, to maintain efficiency.

Another important aspect of maintenance is lubrication. Machines that are not adequately lubricated can suffer from increased friction, leading to wear and tear of components. Always refer to the manufacturer’s manual for recommended lubrication schedules and suitable lubricants. Additionally, checking for loose bolts and fixtures should be a routine practice. Tightening any loose parts can prevent more significant mechanical issues in the future, ensuring the machine operates smoothly and effectively.

Lastly, keeping an eye on the electrical components and monitoring their condition is essential. Regular inspections will help identify any signs of wear or potential malfunctions early on. By being proactive in maintenance, operators can ensure that their pulp making machines remain in good working order, reducing downtime and enhancing productivity whether for home use or business operations.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.