By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

In today's manufacturing landscape, the precision metal cutting machine plays a pivotal role in ensuring the efficiency and accuracy in production processes. According to a recent industry report by MarketsandMarkets, the global precision metal cutting machine market is expected to reach $15.3 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.1%. This growth is fueled by advancements in technology and the increasing demand for high-quality metal components across sectors such as automotive, aerospace, and electronics.

When selecting a precision metal cutting machine, several critical factors come into play, including cutting speed, tooling adaptability, and software capabilities. A well-chosen machine not only enhances production efficiency but also significantly reduces waste and operational costs. Furthermore, understanding the specific requirements of your projects and integrating the latest technological innovations can lead to a substantial competitive advantage in today's fast-paced manufacturing environment. Thus, making an informed decision when investing in a precision metal cutting machine is essential for businesses aiming to optimize performance and meet the diverse needs of their clientele.

Precision metal cutting machines play a vital role in various industries, including manufacturing, aerospace, and automotive sectors. These machines are specifically designed to achieve high levels of accuracy and efficiency when cutting metal materials. According to a report published by MarketsandMarkets, the precision cutting equipment market is projected to grow from $5.2 billion in 2021 to $6.8 billion by 2026, at a CAGR of 5.6%. This growth is driven primarily by the increasing demand for customized metal parts and components that meet stringent quality standards.

Understanding the applications of precision metal cutting machines is essential for selecting the right equipment for your needs. These machines can be employed in several processes, such as laser cutting, waterjet cutting, and CNC machining, each offering unique advantages. For example, laser cutting machines are known for their speed and precision, making them ideal for complex designs and thin materials. Conversely, waterjet cutting provides versatility in handling a wider variety of materials without introducing heat-affected zones. The right choice largely depends on factors such as material type, thickness, and the required tolerances, making it critical to evaluate your specific operational requirements before making a decision.

When selecting a precision metal cutting machine, there are several key specifications that must be prioritized to ensure efficient and accurate cutting performance. One of the most critical factors is the machine's cutting speed, which directly impacts productivity. According to a recent industry report by the International Association of Metalworking Companies, cutting speeds can vary dramatically between different machines, influencing operational throughput by up to 30%. The choice of cutting speed should align with the materials being processed, as harder materials typically require slower speeds to maintain precision and extend tool life.

Another essential consideration is the machine's power ratings, particularly its motor strength and torque output. Machines with higher horsepower ratings tend to offer better performance in cutting denser metals. A study published in the Journal of Materials Processing Technology indicated that machines with a motor output of at least 15 HP are more effective for robust applications, yielding a 20% increase in productivity when handling tough metals such as stainless steel or titanium. Additionally, examining cutting depths and feed rates is vital. Optimizing these parameters ensures that the machine can accommodate various project requirements without compromising quality or efficiency. By paying close attention to these specifications, manufacturers can choose a cutting machine that aligns with their production needs and enhances overall operational capabilities.

When evaluating cutting technologies for precision metal cutting machines, three prominent options come to the forefront: laser, plasma, and waterjet cutting. Each technology offers distinct advantages and is suited for particular applications.

Laser cutting is renowned for its high precision and ability to cut intricate designs in various materials, including thin metals and non-metals. The focused beam of light results in clean edges and minimal heat-affected zones, making it ideal for applications requiring tight tolerances.

Plasma cutting, on the other hand, excels in cutting thicker materials at a faster pace. It utilizes a jet of ionized gas to melt the metal, allowing for quick cuts in metals up to several inches thick. While plasma cutting may not achieve the same level of precision as laser cutting, its speed and efficiency make it a popular choice for heavy-duty fabrication tasks.

Lastly, waterjet cutting employs a high-pressure stream of water mixed with abrasives, which enables it to cut through a wide array of materials, including metals, glass, and stone. Waterjet technology is especially advantageous for thick materials and complex shapes, as it does not generate heat, preserving the material’s integrity.

In summary, choosing the appropriate cutting technology depends heavily on the specific requirements of the project. Factors such as material type, thickness, desired precision, and production speed should guide the decision-making process to ensure optimal results in the metal cutting process. Each method has its unique strengths and can provide quality solutions when applied to the right scenarios.

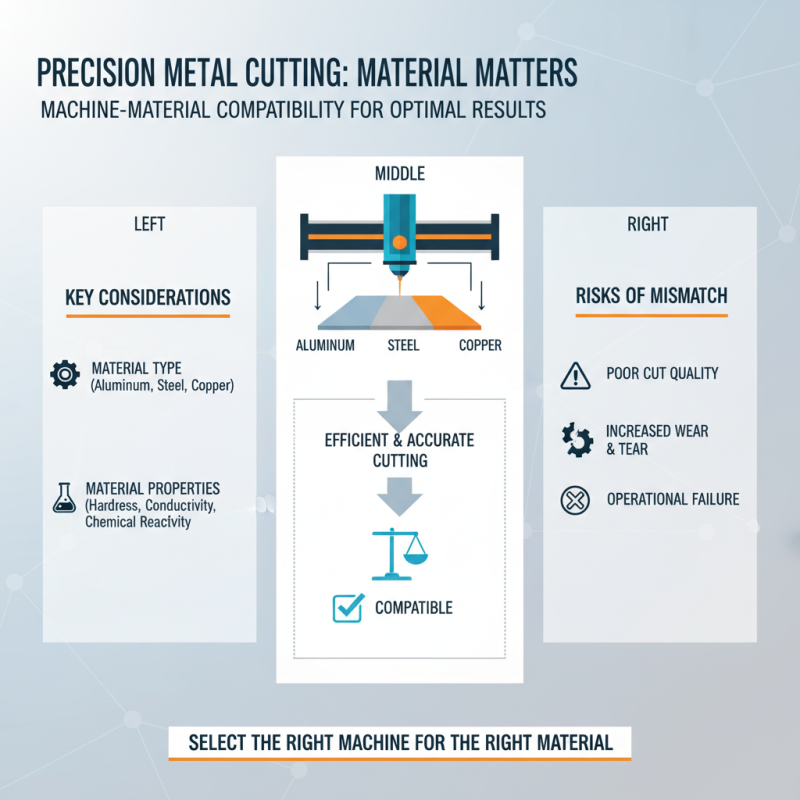

When selecting a precision metal cutting machine, the compatibility of the materials to be processed plays a crucial role in achieving efficient and accurate results. Different machines are designed to handle specific types of materials, such as aluminum, steel, or copper, each requiring distinct cutting techniques and settings. When the machine is not aligned with the material properties, issues such as poor cutting quality, increased wear and tear on the equipment, or even complete operational failure can occur. Therefore, understanding the physical and chemical properties of the materials involved is essential for effective machine selection.

Moreover, material compatibility extends beyond just the type of metal. Factors such as thickness, hardness, and even the presence of coatings or treatments can affect how well a cutting machine can perform. For instance, harder materials require more robust machinery capable of maintaining precision under increased stress. Additionally, selecting the correct cutting tool and technology, whether it’s laser, plasma, or waterjet cutting, can optimize production efficiency and minimize waste. By prioritizing material compatibility in the decision-making process, manufacturers can enhance their cutting capabilities and ensure long-term reliability in their operations.

When investing in a precision metal cutting machine, the initial purchase price is often a focal point for businesses. However, this cost should be weighed against the long-term benefits that such a machine can provide. High-quality machines may require a larger upfront investment, but they often deliver increased efficiency, reduced waste, and lower maintenance costs over time. These factors can significantly impact the overall cost efficiency of the equipment, making it a wise investment in the long run.

Moreover, while cheaper options may seem attractive initially, they can lead to higher operational expenses due to more frequent breakdowns and inferior cutting quality. This can result in costly delays and wasted materials, ultimately diminishing profitability. Therefore, it's crucial to analyze not just the upfront costs but also the potential for increased productivity and durability that come with higher-quality precision metal cutting machines. Choosing the right machine involves a careful consideration of how well the investment aligns with long-term operational goals and cost-saving benefits.

| Tip | Initial Investment ($) | Expected Lifespan (Years) | Annual Maintenance Cost ($) | Estimated Annual Savings ($) | Total 5-Year Cost ($) |

|---|---|---|---|---|---|

| Choose Machine Suitable for Project Size | 15,000 | 10 | 1,200 | 3,000 | 26,000 |

| Evaluate Cutting Speed | 20,000 | 8 | 1,500 | 4,000 | 32,000 |

| Check for Technology Updates | 18,000 | 9 | 1,300 | 3,500 | 30,700 |

| Consider Material Compatibility | 16,500 | 7 | 900 | 2,000 | 24,300 |

| Review Energy Efficiency | 17,000 | 6 | 1,100 | 2,500 | 25,700 |

| Consider After-Sales Support | 19,500 | 11 | 1,600 | 4,200 | 35,900 |

| Read User Reviews | 14,000 | 5 | 800 | 1,500 | 22,500 |

| Consider Scalability | 22,000 | 12 | 1,400 | 5,000 | 43,800 |

| Assess Training Requirements | 21,000 | 10 | 1,300 | 4,600 | 33,800 |

| Request Demonstrations | 23,500 | 11 | 1,700 | 5,500 | 43,700 |

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.