By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

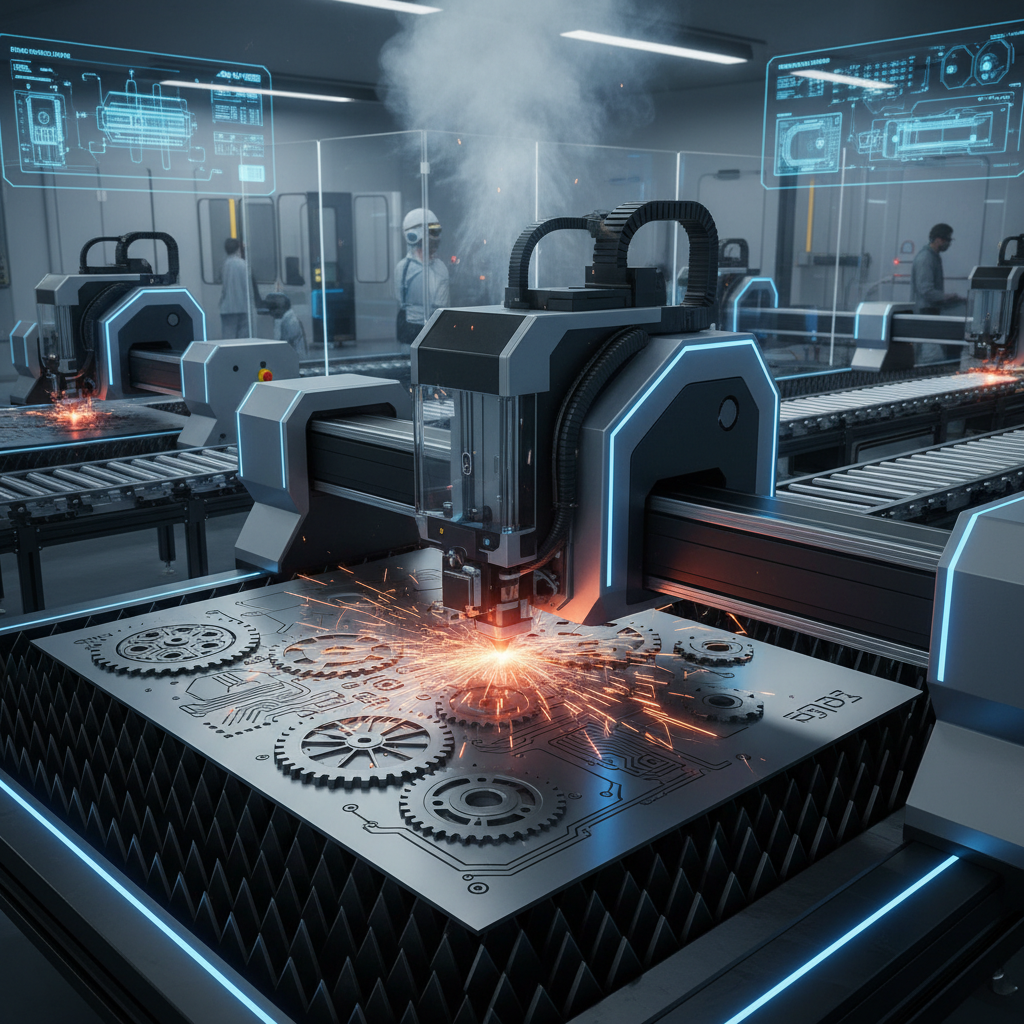

As the industry evolves, the demand for precision cutting solutions continues to rise, making the choice of an iron laser cutting machine more critical than ever. In 2025, a new generation of machines designed for superior accuracy and efficiency is set to revolutionize metal fabrication. According to Dr. Emily Chen, a leading expert in laser cutting technology, “The advancements in iron laser cutting machines are pushing the boundaries of what is possible in precision engineering, enabling manufacturers to achieve unprecedented levels of detail and speed.”

In this article, we will explore the top five iron laser cutting machines you need to watch for in 2025. These machines not only promise enhanced performance but also incorporate innovative features that cater to the evolving needs of industry professionals. The future of manufacturing lies in the ability to produce intricate designs with flawless precision, and these cutting-edge machines are designed to deliver just that, making them indispensable tools for any fabrication shop aiming to stay ahead in a competitive market.

Join us as we delve into the specifications, advantages, and anticipated impact of these state-of-the-art iron laser cutting machines that are poised to define the future of precision cutting.

Advancements in fiber laser technology are significantly influencing the efficiency of iron cutting processes. As the global fiber laser market continues to expand, projected to reach approximately USD 17.55 billion by 2033, the impact of innovation in this sector cannot be overstated. The latest breakthroughs, such as the introduction of high-power fiber lasers, are redefining industrial metal cutting limits, enabling precision cutting at unprecedented speeds. For instance, recent developments have led to the creation of fiber lasers that deliver up to 30kW of power, enhancing material handling capabilities and increasing productivity across various applications.

Moreover, the overall laser technology market is anticipated to grow significantly, with estimates suggesting it may reach USD 37.26 billion by 2032. This surge in market size is fueled by ongoing technological advancements, which are reshaping competitive dynamics within the industry. Understanding these trends becomes crucial for businesses aiming to stay ahead. Alongside, the sheet metal processing equipment market is also on a growth trajectory, projected to rise from USD 35.51 billion in 2025 to USD 61.78 billion by 2032. This interconnected growth highlights the importance of integrating advanced laser technology into manufacturing processes to improve operational efficiency and precision in cutting applications.

The landscape of iron laser cutting machines is evolving rapidly, with several cutting-edge features anticipated to enhance precision and speed in 2025. Among emerging trends, advancements in automation and AI-driven controls are set to play a pivotal role. These technologies enable machines to optimize cutting parameters in real-time, ensuring consistent quality and reducing material waste. Integrated sensors can monitor the cutting process, allowing for immediate adjustments that enhance accuracy and minimize errors.

Furthermore, the incorporation of advanced optics and high-power lasers is expected to significantly increase cutting speeds while maintaining precision. Innovations in beam delivery systems are improving the focus and stability of laser output, which is essential for achieving intricate designs on various iron thicknesses. As manufacturers adopt digital twin technologies, the ability to simulate and predict machine performance will refine operational strategies, leading to even greater efficiencies in production processes. These advancements collectively promise to revolutionize how industries approach laser cutting, positioning them for substantial gains in productivity and precision.

| Machine Model | Cutting Speed (m/min) | Laser Power (W) | Accuracy (mm) | Material Thickness (mm) |

|---|---|---|---|---|

| Model A | 25 | 2000 | 0.05 | 20 |

| Model B | 30 | 3000 | 0.03 | 15 |

| Model C | 22 | 2500 | 0.04 | 25 |

| Model D | 28 | 3500 | 0.02 | 10 |

| Model E | 26 | 2800 | 0.06 | 18 |

The iron laser cutting equipment market is poised for significant growth by 2025, driven by advancements in technology and increasing demand across various industries. According to a recent report by MarketsandMarkets, the global laser cutting market is expected to reach USD 5.6 billion by 2025, growing at a CAGR of 7.5%. This growth is fueled by the rising need for precision and efficiency in manufacturing processes, particularly in sectors such as automotive, aerospace, and metal fabrication.

Moreover, the increasing adoption of automation and IoT integration in manufacturing is also enhancing the appeal of iron laser cutting machines. Research from Technavio indicates that the adoption rate of laser cutting technologies in various industries will lead to a compounded growth rate of over 9% annually. As industries strive to improve operational efficiencies and reduce waste, the demand for laser cutting technologies that offer high precision and low operational costs is expected to skyrocket. With these trends setting the stage for innovation, the iron laser cutting market will likely see the introduction of advanced machines equipped with enhanced software and more powerful lasers, further pushing the boundaries of what’s possible in cutting technology.

As the demand for precision cutting continues to rise, key manufacturers in the iron laser cutting machinery sector are pushing the boundaries of innovation. Companies like Trumpf and Bystronic are at the forefront, consistently enhancing their technology to improve efficiency and accuracy in cutting processes. Their latest models incorporate advanced features such as adaptive optics and artificial intelligence, enabling real-time adjustments during operation, which significantly enhances the quality of the cut and reduces waste.

Another notable player is Amada, whose recent developments include the integration of automation systems that streamline production workflows and minimize downtime. Their laser-cutting machines are designed to adapt to various materials and thicknesses, making them versatile for a range of industrial applications. Additionally, newcomers like Han’s Laser are making waves with their cost-effective solutions that do not compromise on quality, thus appealing to small and medium enterprises looking to invest in cutting-edge technology.

As we look towards 2025, these manufacturers highlight a promising future for iron laser cutting machinery with their commitment to innovation and excellence.

As the demand for precision cutting technology continues to rise, investing in top-tier iron laser cutting machines is becoming increasingly strategic for manufacturers. The cost-benefit analysis for 2025 emphasizes not only the initial investment but also the long-term savings and efficiency gains these machines can provide. With the sheet metal processing equipment market projected to expand significantly, companies need to evaluate their options carefully, considering both the financial outlay and the potential for enhanced productivity.

In this context, the anticipated growth in related markets, such as the CNC plasma cutting machines and laser welding markets, signals a strong trend toward advanced cutting technologies. As these sectors evolve, they present opportunities for manufacturers to upgrade their equipment, thereby improving precision and reducing operational costs. By focusing on integrated solutions that offer cutting-edge features and durability, businesses can ensure that their investments yield substantial returns in 2025 and beyond.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.