By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

As manufacturing processes evolve, the importance of precision in metal cutting cannot be overstated. According to a report by the International Federation of Robotics, the global market for precision metal cutting machines is expected to grow by 7% annually, highlighting the increasing demand for efficient and high-quality manufacturing solutions. This growth is driven by the rising need for accuracy in various industries, including aerospace, automotive, and electronics, where tolerances are critical.

Expert in the field, Dr. Emily Hart, a leading researcher at the Metalworking Institute, emphasizes this trend by stating, “Investing in advanced precision metal cutting machines not only increases productivity but also reduces material waste, ultimately contributing to a more sustainable manufacturing ecosystem.” Her insights underscore the necessity for manufacturers to adopt cutting-edge technology to meet modern demands and remain competitive.

In 2023, we will explore the top 10 precision metal cutting machines that epitomize efficiency and innovation. These machines are not only designed to enhance productivity but also to improve accuracy and reduce operational costs. As we delve into the specifics of these technologies, it becomes clear that selecting the right precision metal cutting machine is paramount for any manufacturing operation aiming for success in today’s fast-paced industry landscape.

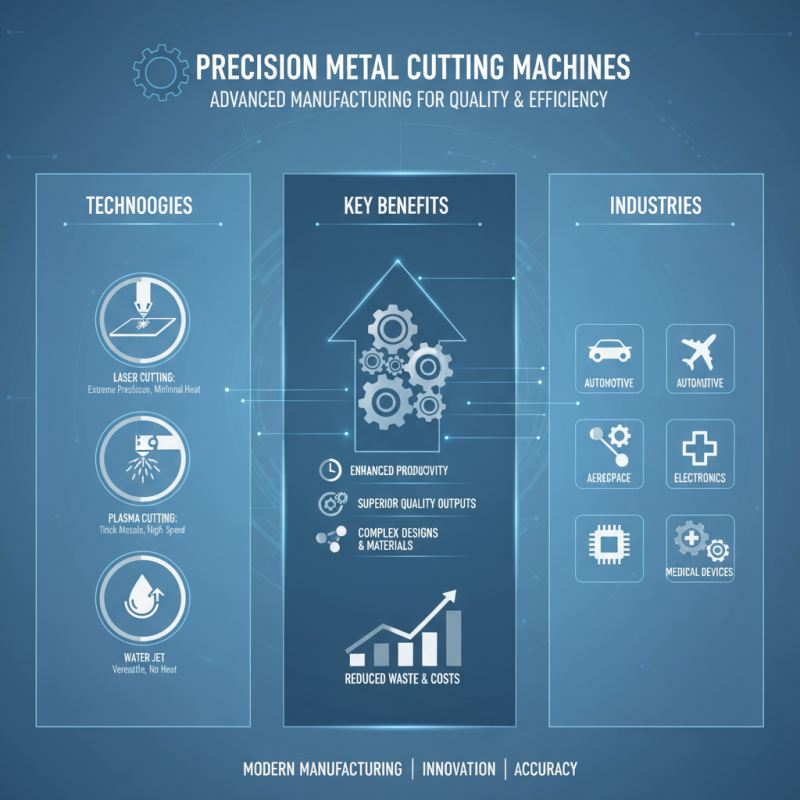

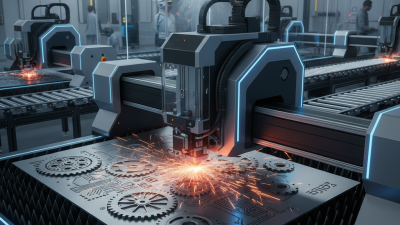

Precision metal cutting machines play a crucial role in modern manufacturing, enhancing productivity and ensuring high-quality outputs across various industries. These machines utilize advanced technologies to achieve precise cuts in a range of materials, including metals, ensuring that components meet the exact specifications required for complex assemblies. By utilizing tools such as lasers, plasma, and water jets, manufacturers can produce intricate designs that would be challenging or impossible to achieve with traditional cutting methods.

The importance of these machines extends beyond mere accuracy; they significantly reduce waste, lower production costs, and improve overall efficiency. With the capability to operate at higher speeds and with greater consistency, precision metal cutting machines allow manufacturers to keep pace with rising demands while maintaining superior quality standards. As a result, industries such as aerospace, automotive, and electronics increasingly rely on these technologies to enhance their competitive edge in a rapidly evolving market landscape, making precision cutting an indispensable element of efficient manufacturing processes.

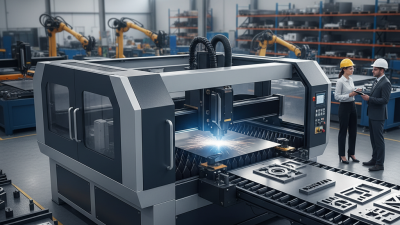

When selecting a precision metal cutting machine for your manufacturing needs, several key features should be considered to ensure efficiency and effectiveness. First and foremost, the machine's cutting speed and feed rate are crucial, as they directly impact productivity. Machines equipped with advanced servo drives often provide a more consistent and higher speed, enabling faster cycle times without compromising on precision.

Another important feature to evaluate is the machine's cutting technology. Plasma cutting, waterjet cutting, and laser cutting each offer different advantages based on the material being processed and the desired finish. Understanding the specific requirements of your projects will help you choose a machine that aligns with your production goals. Additionally, features such as ease of automation and compatibility with CAD/CAM systems can significantly enhance operational workflow.

**Tip:** When choosing a metal cutting machine, consider investing in models that come with comprehensive software support, facilitating easier integration with your existing manufacturing processes.

Another consideration is maintenance and support. Look for machines that are designed for easy maintenance and come with reliable customer service. A machine's longevity and performance largely depend on how well it is maintained. Additionally, having access to rapid support can minimize downtime and ensure continuous operation.

**Tip:** Regular training for your operators can also maximize the efficiency of your equipment, as well-trained personnel can better manage the machine's features and troubleshoot any issues that arise.

| Machine Model | Cutting Method | Max Cutting Thickness (mm) | Cutting Speed (m/min) | Precision (mm) | Special Features |

|---|---|---|---|---|---|

| Model A | Laser Cutting | 30 | 25 | 0.02 | Auto-Calibration |

| Model B | Plasma Cutting | 35 | 20 | 0.1 | Portable Design |

| Model C | Water Jet Cutting | 60 | 15 | 0.05 | Eco-Friendly Operation |

| Model D | Mechanical Cutting | 25 | 10 | 0.03 | High Speed Performance |

| Model E | Laser Cutting | 20 | 30 | 0.01 | User-Friendly Interface |

| Model F | Plasma Cutting | 40 | 18 | 0.07 | High Efficiency |

| Model G | Water Jet Cutting | 50 | 12 | 0.04 | Versatile Material Compatibility |

| Model H | Mechanical Cutting | 30 | 11 | 0.06 | Robust Construction |

| Model I | Laser Cutting | 25 | 22 | 0.02 | Compact Design |

| Model J | Plasma Cutting | 45 | 17 | 0.05 | Durable Components |

In 2023, precision metal cutting machines are crucial for efficient manufacturing, catering to industries that require exact specifications and high durability. These machines incorporate advanced technologies that enhance cutting precision, speed, and overall productivity. In this detailed review, we explore the top 10 metal cutting machines available, highlighting their features, operational strengths, and suitability for various manufacturing needs.

**Tip:** When selecting a precision metal cutting machine, consider not only the cutting speed but also the machine's ability to handle different materials. A versatile machine can adapt to a variety of tasks, maximizing your production capabilities. Additionally, pay attention to the maintenance requirements, as a machine that is easy to maintain can save you time and money in the long run.

Moreover, investing in a machine with automation capabilities can significantly elevate your manufacturing process. Automated systems reduce human error and increase consistency, which is critical in mass production environments. It's advisable to assess the integration options with existing systems to ensure a seamless workflow.

**Tip:** Always seek machines with robust support and training options from manufacturers. Adequate support can enhance your staff's proficiency, ensuring that you make the most of your equipment's capabilities. Exploring user reviews and seeking recommendations can also provide insight into reliability and performance before making a purchase.

When evaluating precision metal cutting machines for efficient manufacturing in 2023, understanding the performance metrics is essential. Key performance indicators include cutting speed, precision tolerance, machine durability, and ease of maintenance. Machines that offer superior cutting speeds without compromising accuracy are crucial for boosting productivity. Additionally, machines equipped with advanced cooling systems tend to have improved durability, which can significantly reduce downtime and maintenance costs, thus enhancing overall efficiency.

Tips for selecting the right cutting machine include assessing the specific needs of your manufacturing process. Consider the materials you will be working with, as different machines may excel with various metal types. It's also beneficial to review the machine's operational capabilities and how they align with your production goals. Investing in a machine that not only meets current demands but also offers scalability for future projects can lead to long-term success.

Moreover, it’s important to analyze user reviews and case studies of other manufacturers who have utilized similar machines. Understanding their experiences with performance metrics can provide valuable insights and prevent potential pitfalls. By focusing on the right metrics and leveraging efficient machines, manufacturers can achieve enhanced production rates and superior quality outcomes in their projects.

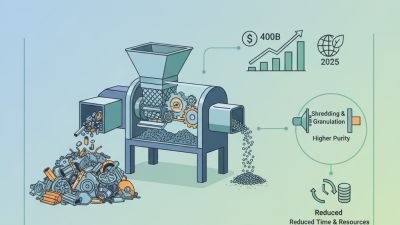

The field of precision metal cutting technology is rapidly evolving, with exciting trends anticipated to revolutionize manufacturing processes in the coming years. As industries increasingly embrace automation and smart manufacturing, the integration of advanced technologies such as artificial intelligence (AI) and machine learning is becoming more prevalent. According to a recent report by the International Federation of Robotics, the adoption of industrial robots in metal cutting applications is expected to grow by over 10% annually through 2025, highlighting the industry's shift towards more streamlined and efficient operations.

Moreover, the push for sustainability is driving innovations in precision metal cutting technologies. The use of cutting-edge materials and techniques can significantly reduce waste and energy consumption, essential factors as manufacturers seek to minimize their environmental impact. A study from the National Institute of Standards and Technology indicates that implementing advanced cutting technologies could reduce cycle times by up to 30%, ensuring full compliance with both efficiency and sustainability standards.

Tips: To stay competitive in this dynamic landscape, it's crucial for manufacturers to continuously invest in training their workforce on the latest technologies and practices. Additionally, exploring collaborations with research institutions and technology providers can foster innovation and open new avenues for efficiency in metal cutting processes. Embracing a proactive approach to technology integration will not only enhance operational capabilities but also prepare businesses for future challenges in the manufacturing sector.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.