By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

In the ever-evolving landscape of manufacturing technology, the choice of equipment can significantly influence production efficiency and quality. Specifically, when it comes to precision processing, selecting the right laser metal cutting machine is crucial for any business looking to stay competitive. Renowned industry expert Dr. Emily Harris once remarked, "The right laser metal cutting machine not only enhances precision but also optimizes productivity, making it a vital investment for any metal fabrication company."

As businesses seek to streamline their operations and improve output, understanding the key factors involved in selecting the best laser metal cutting machine becomes essential. From evaluating performance and technology to considering operational costs and maintenance, these elements can determine the long-term success of a company’s manufacturing capabilities. With this guide, we aim to provide valuable insights that will help you make an informed decision in choosing the ideal laser metal cutting machine for your specific needs.

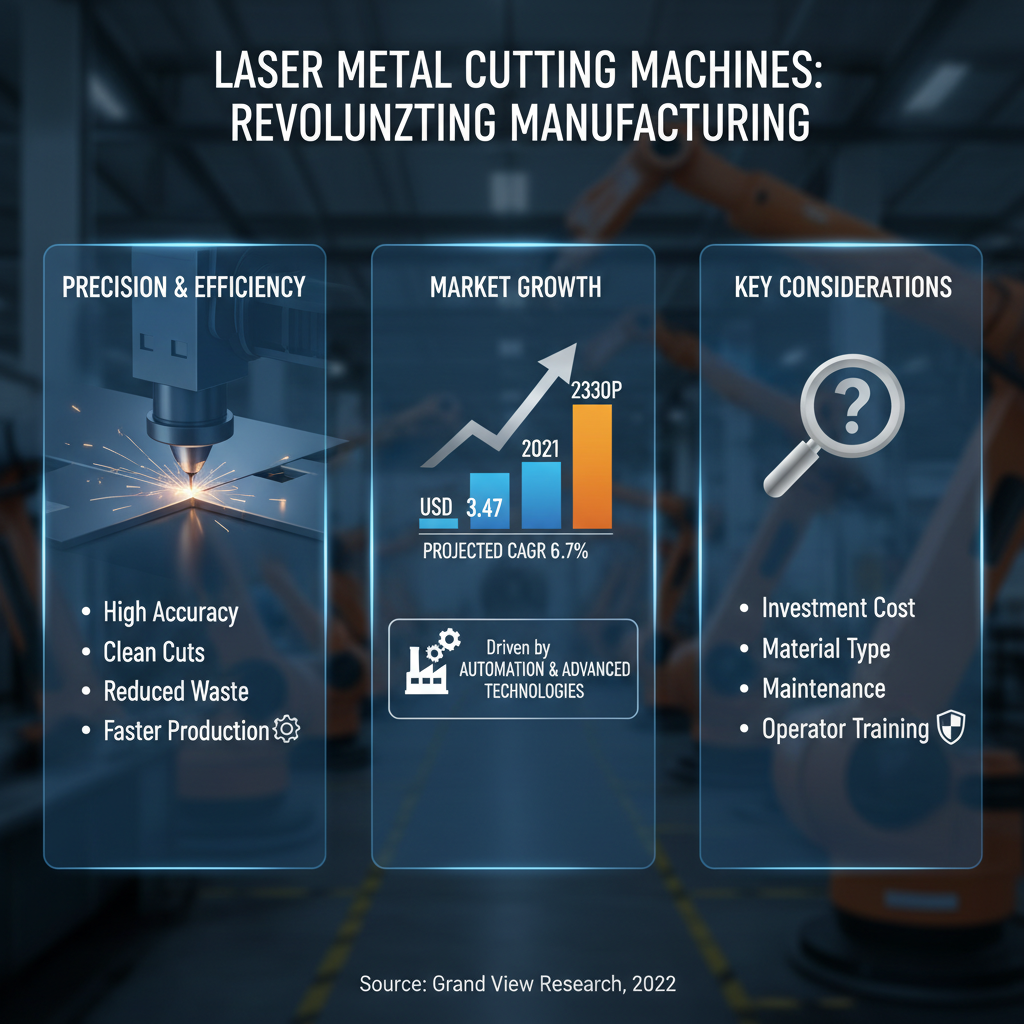

Laser metal cutting machines have revolutionized the manufacturing industry by offering precision and efficiency. Understanding their basics is crucial for anyone considering an investment. According to a market research report by Grand View Research, the global laser cutting machine market size was valued at USD 3.47 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 6.7% from 2022 to 2030. This growth is largely driven by the increasing adoption of automation and advanced manufacturing technologies.

The principle behind laser metal cutting involves focusing a high-power laser beam onto the material, which melts or vaporizes the metal. Key factors influencing the performance include the laser type—CO2 or fiber lasers are most common—wattage, and cutting speed. Fiber lasers, in particular, are gaining popularity due to their efficiency in cutting reflective materials like copper and aluminum, noted for their speed and lower operational costs. A report by Markets and Markets highlighted that fiber laser cutting machines could reduce energy consumption by up to 30% compared to traditional methods, making them an environmentally and economically favorable choice.

When selecting the best laser metal cutting machine, several key factors should be considered to ensure optimal performance for different applications. The global laser cutting equipment market has shown resilience, with the industry projected to recover and grow, particularly as innovations in technology enhance efficiency. According to market research, the laser processing equipment market is expected to expand significantly, with a compound annual growth rate (CAGR) of approximately 7.3% from 2025 to 2032. This growth is driven primarily by the increasing demand from automotive and construction sectors, which rely heavily on precision cutting tools.

Choosing between different laser technologies is crucial. The market divides equipment into various types, including fiber laser, CO2 laser, and solid-state lasers, each offering unique advantages depending on the materials being processed. Fiber lasers dominate due to their efficiency and ability to cut reflective metals, while CO2 lasers are preferred for non-metallic materials. Understanding these distinctions, alongside the machine's functionality—whether semi-automatic or robotic—can greatly impact production efficiency and cost-effectiveness.

As industries lean towards automation, integrating advanced laser systems can enhance operational capabilities and drive significant growth in production outputs.

When selecting a laser cutting machine, understanding the compatibility of materials is crucial. Advanced laser cutting technologies can efficiently handle a variety of materials, including metals, plastics, and wood, but not all machines are suited for every material type. For instance, high-powered CO2 lasers excel in cutting non-metal materials, while fiber lasers are specifically designed for cutting metals with precision and speed. This distinction is vital for businesses aiming to optimize their production processes and meet diverse customer needs.

Recent industry reports indicate a significant increase in demand for machines that can seamlessly process multiple materials. In 2025, the laser cutting market is projected to expand further, with innovations enhancing compatibility and performance across various materials. For example, recent developments in hybrid technologies combined with nanocomposite materials are also influencing the choice of machines, as businesses in sectors such as manufacturing and crafting seek versatile solutions. When making a purchase, it's essential to scrutinize the machine's specifications, focusing on power, wavelength, and the materials it can effectively cut, ensuring it aligns with your specific application requirements.

| Material Type | Laser Type | Max Thickness (mm) | Cutting Speed (m/min) | Typical Applications |

|---|---|---|---|---|

| Mild Steel | Fiber Laser | 20 | 20 | Structural Components |

| Stainless Steel | Fiber Laser | 15 | 15 | Industrial Equipment |

| Aluminum | CO2 Laser | 12 | 18 | Aerospace Components |

| Copper | Fiber Laser | 6 | 10 | Electrical Connectors |

| Brass | Fiber Laser | 8 | 12 | Ornamental Parts |

| Titanium | Fiber Laser | 10 | 8 | Medical Instruments |

| Nickel Alloys | Fiber Laser | 5 | 5 | Aerospace Components |

| Tool Steel | Fiber Laser | 8 | 6 | Manufacturing Tools |

| High Carbon Steel | CO2 Laser | 12 | 14 | Construction Materials |

| Plastic Coated Metals | CO2 Laser | 6 | 12 | Decorative Items |

When evaluating laser metal cutting machines, cutting speed and precision are critical factors that cannot be overlooked. Cutting speed refers to how quickly the machine can move through the material, which directly influences productivity. A higher cutting speed can significantly reduce production times, allowing for more efficient workflow, especially in high-demand environments.

However, it’s essential to balance speed with precision; a machine that cuts too quickly may compromise the quality of the edges, leading to rough cuts and the need for additional finishing processes.

Precision in laser cutting, often measured in terms of tolerances, ensures that the final product meets the exact specifications required for the project. This is particularly important in industries such as aerospace and automotive, where even minor discrepancies can lead to major failures. When selecting a machine, consider its ability to maintain consistent precision across various materials and thicknesses.

Advanced laser cutting machines often come equipped with features like dynamically focusing and adaptive technology, enhancing their ability to deliver precise results regardless of cutting conditions. Prioritizing both cutting speed and precision will ultimately contribute to better operational efficiency and product quality.

When selecting a laser metal cutting machine, maintenance and support options are pivotal elements to consider. According to industry reports, the Metal Fabrication Service Market is expected to reach approximately $23.37 billion in 2024, indicating a robust demand for efficient and reliable cutting solutions. Given this growth, manufacturers are increasingly emphasizing the importance of after-sales support and maintenance services to enhance operational longevity and efficiency of laser cutters.

Recent guidance on safely managing laser cutting equipment highlights the necessity for regular maintenance to mitigate risks and ensure optimal performance. The U.S. Army's decision to cut "unnecessary maintenance" on vehicles underscores the need for a more streamlined approach, which could also apply to the maintenance of laser cutting machinery. When investing in a laser cutter, it's crucial to evaluate the manufacturer's maintenance schedule and support options, as they can significantly influence the machine's operational efficiency and dependability over time. As the market for precision laser engraving machines is projected to surge, reaching around $6.67 billion by 2035, businesses should prioritize machines that offer comprehensive support to capitalize on this growth effectively.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.