By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

In the rapidly evolving landscape of manufacturing and fabrication, the aluminium laser cutting machine has emerged as a pivotal tool for efficiency and precision. This advanced technology utilizes high-powered lasers to achieve clean and intricate cuts in aluminium sheets, making it a favored choice across various industries, from automotive to aerospace. The ability to control the cutting process with exceptional accuracy not only enhances product quality but also significantly reduces material waste, optimizing both time and cost.

As businesses strive to improve their production capabilities and meet the demands of modern consumers, understanding the benefits of aluminium laser cutting machines becomes increasingly important. These machines offer unparalleled versatility, allowing for the execution of complex designs that traditional cutting methods struggle to achieve. Furthermore, the speed at which these machines operate can lead to more streamlined production processes, ultimately increasing competitiveness in the market. In this guide, we will explore the various advantages of using aluminium laser cutting machines and how they can transform manufacturing operations, ensuring companies stay at the forefront of innovation.

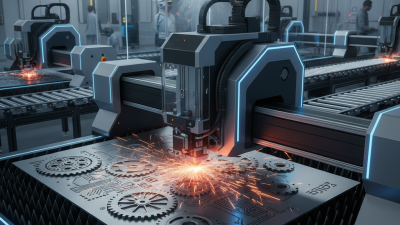

Aluminium laser cutting technology has revolutionized the way industries handle metal fabrication, offering precision and efficiency that traditional methods struggle to match. This technology involves the use of a high-powered laser beam to melt and vaporize the metal, allowing for clean cuts with intricate details that would be difficult to achieve otherwise. The process is highly controlled, ensuring minimal material waste and reducing the need for additional finishing processes, which further streamlines production.

One of the primary benefits of aluminium laser cutting is its adaptability. It can effectively cut through various thicknesses of aluminium, making it suitable for a wide range of applications, from automotive parts to architectural elements. Moreover, laser cutting is not only fast but also capable of producing repeatable results, which is crucial for industries where precision is paramount. The ability to create complex shapes and designs without the need for extensive tooling or setup time enhances the overall efficiency and reduces lead times in manufacturing processes.

Aluminium laser cutting machines are integral to modern manufacturing, boasting several key components that enhance their functionality and precision. One of the primary components is the laser source, which generates the beam capable of cutting through thick aluminium plates with high efficiency. According to a report by Research and Markets, the adoption of fiber laser technology is projected to increase significantly, contributing to a CAGR of over 15% in the aluminium cutting market by 2025. This type of laser source is favored for its high energy efficiency and minimal maintenance requirements, making it ideal for industries such as automotive and aerospace.

Another crucial element is the motion control system, which ensures that the laser head moves with precision across the material's surface. Advanced CNC systems allow for intricate designs to be cut with high accuracy. Industry data indicates that accurate motion control can enhance production efficiency by up to 30%, reducing material wastage and increasing overall throughput. Additionally, the integration of automated loading and unloading systems is becoming increasingly popular, as it further streamlines the cutting process and reduces labor costs. These advancements underscore the importance of investing in quality components to optimize the performance of aluminium laser cutting machines in various industrial applications.

| Component | Description | Benefits | Typical Material Thickness |

|---|---|---|---|

| Laser Source | The energy source that generates the laser beam. | High precision cutting, minimal heat affected zone. | Up to 25 mm |

| Control System | Manages the movement of the laser cutting head. | Enhanced cut accuracy and efficiency. | Varies based on application |

| Optics | Lenses and mirrors that focus the laser beam. | Improves beam quality for cleaner cuts. | Commonly up to 15 mm |

| Assist Gas System | Supplies gas like oxygen or nitrogen during cutting. | Prevents oxidation and improves finish quality. | Up to 20 mm |

| Workholding System | Fixtures and clamps to hold workpieces in place. | Ensures stability and precision during cuts. | Depends on design |

Laser cutting technology has revolutionized the way aluminium is processed, offering a range of advantages that traditional cutting methods cannot match. One of the primary benefits of using laser cutting for aluminium processing is its precision. Laser machines can achieve intricate designs with outstanding accuracy, allowing for complex shapes to be cut from sheets of aluminium without the need for excessive material removal. This high level of precision extends to tight tolerances, which is critical in industries where exact measurements are essential, such as aerospace and automotive manufacturing.

Another significant advantage of laser cutting is its efficiency. The laser cutting process generates minimal heat, reducing the risk of warping or altering the material's properties during cutting. This not only preserves the structural integrity of the aluminium but also enhances the overall quality of the finished product. Furthermore, laser cutting equipment operates at high speeds, which translates to shorter production times and lower operational costs. The ability to cut, engrave, and mark continuously without extensive tooling changes makes it a versatile option for manufacturers looking to streamline their operations. Overall, these advantages make laser cutting an invaluable technology for aluminium processing, enabling businesses to achieve superior results while maximizing productivity.

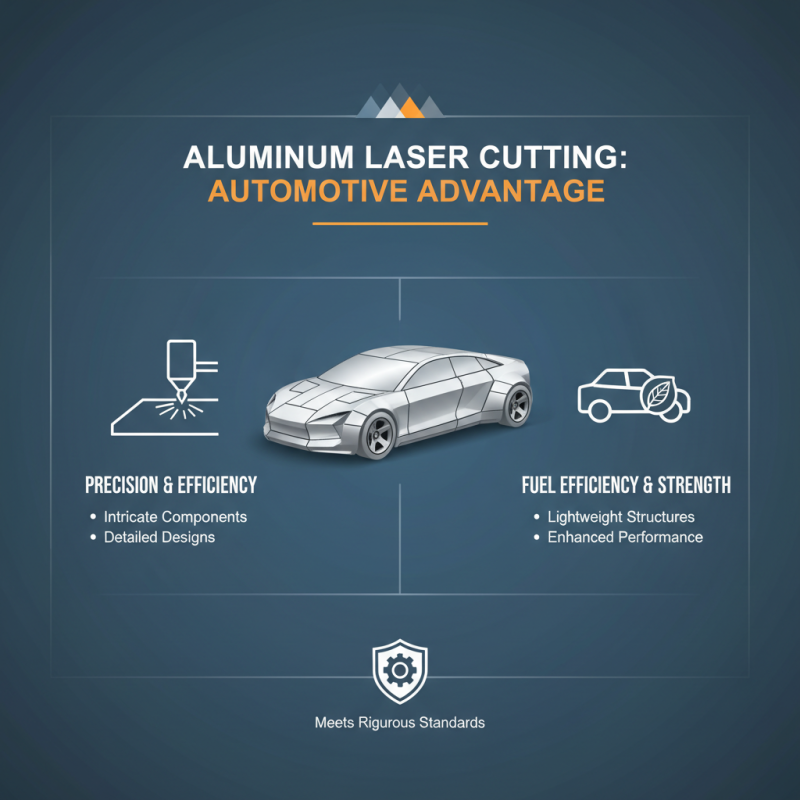

Aluminium laser cutting technology has become an indispensable asset across various industries due to its precision and efficiency. In the automotive sector, manufacturers utilize this technology for creating intricate components and lightweight structures that enhance fuel efficiency without compromising on strength. The precise cutting capabilities allow for detailed designs that meet the rigorous standards required in vehicle production, making aluminium parts that are both functional and aesthetically pleasing.

In the aerospace industry, the lightweight nature of aluminium combined with laser cutting technology facilitates the manufacturing of complex parts with minimal waste. This is crucial in aircraft design, where every gram contributes to overall performance and fuel consumption. Laser cutting provides the ability to produce highly customized components that are essential for modern aerospace applications, including brackets, mounts, and fuselage parts.

Furthermore, the construction and architectural sectors leverage aluminium laser cutting for creating distinctive façade elements and structural components. The versatility of aluminium allows architects to push the boundaries of design, creating visually striking structures that also offer durability and weather resistance. The ability to cut intricate patterns efficiently ensures that the final products meet both functional requirements and dynamic aesthetic visions, further expanding the scope of applications in these industries.

Maintaining aluminium laser cutting machines is crucial to ensure their longevity and optimal performance. Regular maintenance can significantly reduce downtime and enhance cutting quality. One of the most important tips is to keep the machine clean. Dust, metal shavings, and residue can accumulate and affect the laser's efficiency. Regularly inspect and clean the optics to maintain optimal beam quality and prevent performance degradation.

Another essential aspect of maintenance is to monitor the gas levels. The type of gas used, such as nitrogen or oxygen, can influence the quality of the cut. Low gas levels can lead to incomplete cuts and increased wear on the machine. Always ensure that the gas supply is at adequate levels and check for leaks.

Moreover, it’s vital to conduct routine checks of the machine's moving parts, such as the rails and bearings. Lubrication is necessary to minimize friction and prevent wear. Pay attention to any unusual noises or vibrations during operation, as these could indicate underlying issues that need immediate attention. By following these maintenance tips, you can prolong the life of aluminium laser cutting machines and maintain high cutting standards.

By using this site you agree to the use of cookies by the company in accordance with the Privacy Policy

Have a questions or want to know more about our company? We'll be expecting you.